Journal Description

Vibration

Vibration

is a peer-reviewed, open access journal of vibration science and engineering, published quarterly online by MDPI.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- High Visibility: indexed within Scopus, ESCI (Web of Science), and other databases.

- Journal Rank: CiteScore - Q2 (Engineering (miscellaneous))

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 29.3 days after submission; acceptance to publication is undertaken in 2.9 days (median values for papers published in this journal in the second half of 2024).

- Recognition of Reviewers: reviewers who provide timely, thorough peer-review reports receive vouchers entitling them to a discount on the APC of their next publication in any MDPI journal, in appreciation of the work done.

Impact Factor:

1.9 (2023);

5-Year Impact Factor:

2.0 (2023)

Latest Articles

Soil–Structure Interaction and Damping by the Soil—Effects of Foundation Groups, Foundation Flexibility, Soil Stiffness and Layers

Vibration 2025, 8(1), 5; https://doi.org/10.3390/vibration8010005 (registering DOI) - 31 Jan 2025

Abstract

In many tasks of railway vibration, the structure, that is, the track, a bridge, and a nearby building and its floors, is coupled to the soil, and the soil–structure interaction and the damping by the soil should be included in the analysis to

[...] Read more.

In many tasks of railway vibration, the structure, that is, the track, a bridge, and a nearby building and its floors, is coupled to the soil, and the soil–structure interaction and the damping by the soil should be included in the analysis to obtain realistic resonance frequencies and amplitudes. The stiffness and damping of a variety of foundations is calculated by an indirect boundary element method which uses fundamental solutions, is meshless, uses collocation points on the boundary, and solves the singularity by an appropriate averaging over a part of the surface. The boundary element method is coupled with the finite element method in the case of flexible foundations such as beams, plates, piles, and railway tracks. The results, the frequency-dependent stiffness and damping of single and groups of rigid foundations on homogeneous and layered soil and the amplitude and phase of the dynamic compliance of flexible foundations, show that the simple constant stiffness and damping values of a rigid footing on homogeneous soil are often misleading and do not represent well the reality. The damping may be higher in some special cases, but, in most cases, the damping is lower than expected from the simple theory. Some applications and measurements demonstrate the importance of the correct damping by the soil.

Full article

Open AccessArticle

Experiment-Based Design of Stirling Cryocooler Compressor Using Response-Controlled Testing

by

Suna Güçyılmaz Çetin, Taylan Karaağaçlı and Ahmet H. Ertas

Vibration 2025, 8(1), 4; https://doi.org/10.3390/vibration8010004 - 30 Jan 2025

Abstract

Flexure-based Stirling cryocooler compressors are a critical technology in providing cryogenic temperatures in various advanced engineering fields, such as aerospace, defense, and medical imaging. The most challenging problem in the design of this type of compressor is achieving a precise alignment that preserves

[...] Read more.

Flexure-based Stirling cryocooler compressors are a critical technology in providing cryogenic temperatures in various advanced engineering fields, such as aerospace, defense, and medical imaging. The most challenging problem in the design of this type of compressor is achieving a precise alignment that preserves small gaps between the components moving relative to each other and avoids severe friction and wear. This paper introduces a novel experimental procedure for designing Stirling cryocooler compressors, leveraging a recently developed nonlinear experimental modal analysis method known as response-controlled stepped-sine testing (RCT). The alignment in a compressor prototype was significantly improved in light of a series of RCT with base excitation. The enhanced compressor design was subsequently validated though a series of constant-current tests, which confirmed the elimination of the sticking/locking phenomenon observed in the initial design. Furthermore, an indirect harmonic force surface (HFS)-based approach proposed for weakly nonlinear systems was extended to identify the high and nonlinear damping (up to a 65% hysteretic modal damping ratio) observed in the enhanced compressor design due to excessive friction. As another contribution, it was shown that the extrapolation of the HFS gives accurate results in the prediction of the nonlinear modal parameters at response levels where no experimental data are available. In light of these findings, it was concluded that the enhanced design needs further design modifications to further decrease the friction and wear between the moving parts. Overall, this study provides valuable insights for designing cryocooler compressors, with implications for aerospace and medical applications.

Full article

(This article belongs to the Special Issue Vibration Damping)

►▼

Show Figures

Figure 1

Figure 1

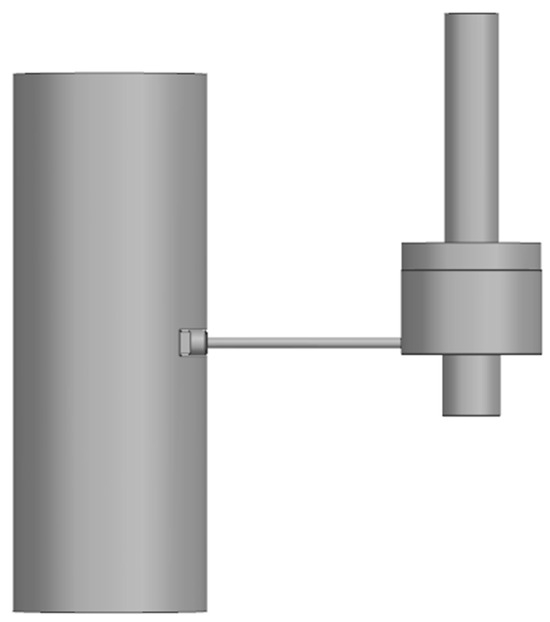

<p>Split linear Stirling cryocooler.</p> Full article ">Figure 2

<p>Flexure bearings used in Stirling cryocooler compressors.</p> Full article ">Figure 3

<p>(<b>a</b>) Small gaps in a typical flexure-based Stirling cryocooler; (<b>b</b>) flexure bearing.</p> Full article ">Figure 4

<p>Experiment-based design procedure for flexure-based Stirling cryocooler compressors.</p> Full article ">Figure 5

<p>Experimental setup for preliminary compressor prototype.</p> Full article ">Figure 6

<p>Harmonic responses of the piston measured during constant-current sine tests of the preliminary compressor prototype conducted at 1 A amplitude level and different excitation frequencies.</p> Full article ">Figure 7

<p>Considerable wear at the inner face of the magnet holder due to friction between the magnet holder and the cylinder.</p> Full article ">Figure 8

<p>Simplified models of the preliminary compressor prototype: (<b>a</b>) System A; (<b>b</b>) System B; (<b>c</b>) System C; (<b>d</b>) System D.</p> Full article ">Figure 9

<p>Response-controlled testing with base excitation.</p> Full article ">Figure 10

<p>Quasi-linear FRFs measured by response-controlled testing with base excitation: (<b>a</b>) System A; (<b>b</b>) System B; (<b>c</b>) System C.</p> Full article ">Figure 11

<p>Natural frequencies and viscous modal damping ratios identified from measured quasi-linear FRFs of simplified compressor models.</p> Full article ">Figure 12

<p>A simplified model corresponding to the enhanced compressor design: (<b>a</b>) schematic view; (<b>b</b>) response-controlled test configuration.</p> Full article ">Figure 13

<p>Natural frequency and viscous modal damping ratio obtained from quasi-linear FRFs of simplified model corresponding to the enhanced compressor design.</p> Full article ">Figure 14

<p>(<b>a</b>) Schematic view of the enhanced compressor design; (<b>b</b>) enhanced flexure bearing design.</p> Full article ">Figure 15

<p>Experimental setup for the enhanced compressor design.</p> Full article ">Figure 16

<p>(<b>a</b>) Frequency response curves measured from constant-current tests; (<b>b</b>) HFS constructed from measured frequency response curves.</p> Full article ">Figure 17

<p>Constant-response FRFs extracted by cutting the HFS with constant-displacement amplitude planes.</p> Full article ">Figure 18

<p>Variation in the nonlinear modal parameters of the enhanced compressor prototype with respect to the response level: (<b>a</b>) natural frequency; (<b>b</b>) modal damping ratio.</p> Full article ">Figure 19

<p>Variation in the modal constant of the enhanced compressor prototype with respect to the response level.</p> Full article ">Figure 20

<p>Comparison of the constant-current frequency response curves synthesized by using the identified nonlinear modal parameters with the ones directly measured by constant-current sine tests.</p> Full article ">Figure 21

<p>Extrapolated HFS.</p> Full article ">Figure 22

<p>Variation in the nonlinear modal parameters obtained from the extrapolated HFS: (<b>a</b>) natural frequency; (<b>b</b>) modal damping ratio.</p> Full article ">Figure 23

<p>Variation in the modal constant obtained from the extrapolated HFS.</p> Full article ">Figure 24

<p>Comparison of the constant-current frequency response curves synthesized by using the nonlinear modal parameters identified from the extrapolated HFS with the ones directly measured by constant-current sine tests.</p> Full article ">

<p>Split linear Stirling cryocooler.</p> Full article ">Figure 2

<p>Flexure bearings used in Stirling cryocooler compressors.</p> Full article ">Figure 3

<p>(<b>a</b>) Small gaps in a typical flexure-based Stirling cryocooler; (<b>b</b>) flexure bearing.</p> Full article ">Figure 4

<p>Experiment-based design procedure for flexure-based Stirling cryocooler compressors.</p> Full article ">Figure 5

<p>Experimental setup for preliminary compressor prototype.</p> Full article ">Figure 6

<p>Harmonic responses of the piston measured during constant-current sine tests of the preliminary compressor prototype conducted at 1 A amplitude level and different excitation frequencies.</p> Full article ">Figure 7

<p>Considerable wear at the inner face of the magnet holder due to friction between the magnet holder and the cylinder.</p> Full article ">Figure 8

<p>Simplified models of the preliminary compressor prototype: (<b>a</b>) System A; (<b>b</b>) System B; (<b>c</b>) System C; (<b>d</b>) System D.</p> Full article ">Figure 9

<p>Response-controlled testing with base excitation.</p> Full article ">Figure 10

<p>Quasi-linear FRFs measured by response-controlled testing with base excitation: (<b>a</b>) System A; (<b>b</b>) System B; (<b>c</b>) System C.</p> Full article ">Figure 11

<p>Natural frequencies and viscous modal damping ratios identified from measured quasi-linear FRFs of simplified compressor models.</p> Full article ">Figure 12

<p>A simplified model corresponding to the enhanced compressor design: (<b>a</b>) schematic view; (<b>b</b>) response-controlled test configuration.</p> Full article ">Figure 13

<p>Natural frequency and viscous modal damping ratio obtained from quasi-linear FRFs of simplified model corresponding to the enhanced compressor design.</p> Full article ">Figure 14

<p>(<b>a</b>) Schematic view of the enhanced compressor design; (<b>b</b>) enhanced flexure bearing design.</p> Full article ">Figure 15

<p>Experimental setup for the enhanced compressor design.</p> Full article ">Figure 16

<p>(<b>a</b>) Frequency response curves measured from constant-current tests; (<b>b</b>) HFS constructed from measured frequency response curves.</p> Full article ">Figure 17

<p>Constant-response FRFs extracted by cutting the HFS with constant-displacement amplitude planes.</p> Full article ">Figure 18

<p>Variation in the nonlinear modal parameters of the enhanced compressor prototype with respect to the response level: (<b>a</b>) natural frequency; (<b>b</b>) modal damping ratio.</p> Full article ">Figure 19

<p>Variation in the modal constant of the enhanced compressor prototype with respect to the response level.</p> Full article ">Figure 20

<p>Comparison of the constant-current frequency response curves synthesized by using the identified nonlinear modal parameters with the ones directly measured by constant-current sine tests.</p> Full article ">Figure 21

<p>Extrapolated HFS.</p> Full article ">Figure 22

<p>Variation in the nonlinear modal parameters obtained from the extrapolated HFS: (<b>a</b>) natural frequency; (<b>b</b>) modal damping ratio.</p> Full article ">Figure 23

<p>Variation in the modal constant obtained from the extrapolated HFS.</p> Full article ">Figure 24

<p>Comparison of the constant-current frequency response curves synthesized by using the nonlinear modal parameters identified from the extrapolated HFS with the ones directly measured by constant-current sine tests.</p> Full article ">

Open AccessArticle

Methodology for Designing Vibration Devices with Asymmetric Oscillations and a Given Value of the Asymmetry of the Driving Force

by

Mihail D. Gerasimov, Nickolai S. Lubimyi, Andrey A. Polshin, Boris S. Chetverikov and Anastasia Chetverikova

Vibration 2025, 8(1), 3; https://doi.org/10.3390/vibration8010003 - 15 Jan 2025

Abstract

In mechanical engineering, the building industry, and many other branches of industry, vibration machines are widely used, in which circular and directed oscillations predominate in the form of movement of the working equipment. This article examines methods for generating asymmetric oscillations, which are

[...] Read more.

In mechanical engineering, the building industry, and many other branches of industry, vibration machines are widely used, in which circular and directed oscillations predominate in the form of movement of the working equipment. This article examines methods for generating asymmetric oscillations, which are estimated by a numerical parameter, namely by the coefficient of asymmetry of the magnitude of the driving force when changing the direction of action in a directed motion within each period of oscillations. It is shown that for generating asymmetric mechanical vibrations, vibration devices are used, consisting of vibrators of directed vibrations, called stages. These stages form the total asymmetric driving force. The behavior of the total driving force of asymmetric vibrations and the working equipment of the vibration machine are described by analytical equations, which represent certain laws of motion of the mechanical system. This article presents a numerical analysis of methods for obtaining laws of motion for a two-stage, three-stage, and four-stage vibration device with asymmetric oscillations. An analysis of the methodology for obtaining a generalized law of motion for a vibration device with asymmetric oscillations is performed based on the application of polyharmonic oscillation synthesis methods. It is shown that the method of forming the total driving force of a vibration device based on the coefficients of the terms of the Fourier series has limited capabilities. This article develops, substantiates, and presents a generalized method for calculating and designing a vibration device with asymmetric oscillations by the value of the total driving force and a given value of the asymmetry coefficient in a wide range of rational designs of vibration machines. The proposed method is accompanied by a numerical example for a vibration device with an asymmetry coefficient of the total driving force equal to 10.

Full article

(This article belongs to the Special Issue Nonlinear Vibration of Mechanical Systems)

►▼

Show Figures

Figure 1

Figure 1

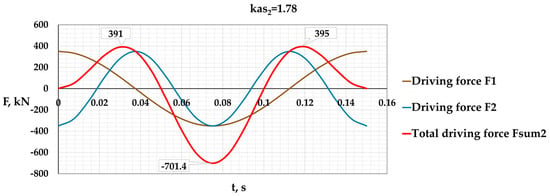

<p>Adding two (<span class="html-italic">F</span><sub>1</sub> and <span class="html-italic">F</span><sub>2</sub>) directed oscillations to obtain the total oscillation by initial conditions [<a href="#B31-vibration-08-00003" class="html-bibr">31</a>]. The asymmetry coefficient of the driving force is <math display="inline"><semantics> <mrow> <msub> <mrow> <msub> <mrow> <mi>k</mi> </mrow> <mrow> <mi>a</mi> <mi>s</mi> <mn>2</mn> </mrow> </msub> <mo>=</mo> <mi>k</mi> </mrow> <mrow> <mi>d</mi> <mn>2</mn> </mrow> </msub> <mo>=</mo> <mn>1.78</mn> </mrow> </semantics></math>, (<span class="html-italic">F<sub>sum</sub></span><sub>2</sub>).</p> Full article ">Figure 2

<p>Addition of three directional oscillations (<span class="html-italic">F</span><sub>1</sub> and <span class="html-italic">F</span><sub>2</sub>, <span class="html-italic">F</span><sub>3</sub>) to obtain a total oscillation (<span class="html-italic">F<sub>sum</sub></span><sub>3</sub>) with asymmetry of the driving force <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>k</mi> </mrow> <mrow> <mi>a</mi> <mi>s</mi> <mn>3</mn> </mrow> </msub> <mo>=</mo> <msub> <mrow> <mi>k</mi> </mrow> <mrow> <mi>d</mi> <mn>3</mn> </mrow> </msub> <mo>=</mo> <mn>3.0</mn> </mrow> </semantics></math>, [<a href="#B46-vibration-08-00003" class="html-bibr">46</a>].</p> Full article ">Figure 3

<p>Addition of four directional oscillations (<span class="html-italic">F</span><sub>1</sub> and <span class="html-italic">F</span><sub>2</sub>, <span class="html-italic">F</span><sub>3</sub>, <span class="html-italic">F</span><sub>4</sub>) to obtain a total oscillation with asymmetry of the driving force <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>k</mi> </mrow> <mrow> <mi>d</mi> </mrow> </msub> <mo>=</mo> <mn>4.0</mn> </mrow> </semantics></math>, (<math display="inline"><semantics> <mrow> <msub> <mrow> <msub> <mrow> <mi>k</mi> </mrow> <mrow> <mi>a</mi> <mi>s</mi> <mn>4</mn> </mrow> </msub> <mo>=</mo> <mi>k</mi> </mrow> <mrow> <mi>d</mi> <mn>4</mn> </mrow> </msub> <mo>=</mo> <mn>3.89</mn> </mrow> </semantics></math>, (<math display="inline"><semantics> <mrow> <msub> <mrow> <mi>F</mi> </mrow> <mrow> <mi>s</mi> <mi>u</mi> <mi>m</mi> <mn>4</mn> </mrow> </msub> </mrow> </semantics></math>)).</p> Full article ">Figure 4

<p>Graph of the change in the asymmetry coefficient (<math display="inline"><semantics> <mrow> <msub> <mrow> <mi>k</mi> </mrow> <mrow> <mi>a</mi> <mi>s</mi> <mi>n</mi> </mrow> </msub> </mrow> </semantics></math>) of the total driving force of the vibration device, formed on the basis of the terms of the Fourier series of the function <math display="inline"><semantics> <mrow> <mo>=</mo> <msup> <mrow> <mi>c</mi> <mi>o</mi> <mi>s</mi> </mrow> <mrow> <mn>12</mn> </mrow> </msup> <mstyle scriptlevel="0" displaystyle="true"> <mfrac> <mrow> <mi>x</mi> </mrow> <mrow> <mn>2</mn> </mrow> </mfrac> </mstyle> </mrow> </semantics></math> for the first six terms (<span class="html-italic">n</span> = 1…6).</p> Full article ">Figure 5

<p>A diagram of a vibration mechanism consisting of <span class="html-italic">n</span> pairs of unbalanced vibrators, each pair of which forms a vibration block, a stage that generates directed oscillations.</p> Full article ">Figure 6

<p>Support reactions of each of the seven pairs of vibrators with the value <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>a</mi> </mrow> <mrow> <mi>k</mi> </mrow> </msub> <mo>=</mo> <mn>1.0</mn> </mrow> </semantics></math> and initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mn>0</mn> </mrow> </semantics></math>.</p> Full article ">Figure 7

<p>The sum of support reactions of all seven pairs of vibrators with the value <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>a</mi> </mrow> <mrow> <mi>k</mi> </mrow> </msub> <mo>=</mo> <mn>1.0</mn> </mrow> </semantics></math> and initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mn>0</mn> </mrow> </semantics></math>.</p> Full article ">Figure 8

<p>Support reactions of each of the seven pairs of vibrators with coefficients <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>a</mi> </mrow> <mrow> <mi>k</mi> <mi>i</mi> </mrow> </msub> <mo>=</mo> <mn>1.0</mn> </mrow> </semantics></math> and initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mstyle scriptlevel="0" displaystyle="true"> <mfrac> <mrow> <mi>π</mi> </mrow> <mrow> <mn>2</mn> </mrow> </mfrac> </mstyle> <mrow> <mo>(</mo> <mi>k</mi> <mo>−</mo> <mn>1</mn> <mo>)</mo> </mrow> </mrow> </semantics></math>, calculated using Equation (26).</p> Full article ">Figure 9

<p>The sum of support reactions of all seven pairs of vibrators with coefficients <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>a</mi> </mrow> <mrow> <mi>k</mi> </mrow> </msub> <mo>=</mo> <mn>1.0</mn> </mrow> </semantics></math> and initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mstyle scriptlevel="0" displaystyle="true"> <mfrac> <mrow> <mi>π</mi> </mrow> <mrow> <mn>2</mn> </mrow> </mfrac> </mstyle> <mrow> <mo>(</mo> <mi>k</mi> <mo>−</mo> <mn>1</mn> <mo>)</mo> </mrow> </mrow> </semantics></math>, calculated using Equation (26).</p> Full article ">Figure 10

<p>Fejer kernel, (<b>a</b>) is for N = 7, (<b>b</b>) is for several Fejer kernels [<a href="#B39-vibration-08-00003" class="html-bibr">39</a>,<a href="#B40-vibration-08-00003" class="html-bibr">40</a>,<a href="#B41-vibration-08-00003" class="html-bibr">41</a>].</p> Full article ">Figure 11

<p>Calculation of simplexes in the process of determining the optimal values of parameters <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>a</mi> </mrow> <mrow> <mn>1</mn> </mrow> </msub> </mrow> </semantics></math> and <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>a</mi> </mrow> <mrow> <mn>2</mn> </mrow> </msub> </mrow> </semantics></math>.</p> Full article ">Figure 12

<p>Values of parameters at the vertices of simplexes and the corresponding values of the dynamic coefficient <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>k</mi> </mrow> <mrow> <mi>d</mi> </mrow> </msub> </mrow> </semantics></math>.</p> Full article ">Figure 13

<p>Calculation graphs of the magnitude of the driving forces of a vibration device with asymmetric oscillations with the total driving force <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>F</mi> </mrow> <mrow> <mi>s</mi> <mi>u</mi> <mi>m</mi> </mrow> </msub> </mrow> </semantics></math> = 10 kN and the specified asymmetry coefficient <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>k</mi> </mrow> <mrow> <mi>a</mi> <mi>s</mi> </mrow> </msub> </mrow> </semantics></math> = 7.0. (<b>a</b>) is support reactions of each of the seven pairs of vibrators with the value <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>F</mi> </mrow> <mrow> <mi>s</mi> <mi>u</mi> <mi>m</mi> </mrow> </msub> </mrow> </semantics></math> = 1 kN and the initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mn>0</mn> </mrow> </semantics></math>; (<b>b</b>) is the sum of the support reactions of all seven pairs of vibrators with the initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mn>0</mn> </mrow> </semantics></math>; (<b>c</b>) is the support reactions of each of the seven pairs of vibrators with the initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mstyle scriptlevel="0" displaystyle="true"> <mfrac> <mrow> <mi>π</mi> </mrow> <mrow> <mn>2</mn> </mrow> </mfrac> </mstyle> <mrow> <mo>(</mo> <mi>k</mi> <mo>−</mo> <mn>1</mn> <mo>)</mo> </mrow> </mrow> </semantics></math>, (<b>d</b>) is the sum of the support reactions of all seven pairs of vibrators with the initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mstyle scriptlevel="0" displaystyle="true"> <mfrac> <mrow> <mi>π</mi> </mrow> <mrow> <mn>2</mn> </mrow> </mfrac> </mstyle> <mrow> <mo>(</mo> <mi>k</mi> <mo>−</mo> <mn>1</mn> <mo>)</mo> </mrow> </mrow> </semantics></math>.</p> Full article ">Figure 13 Cont.

<p>Calculation graphs of the magnitude of the driving forces of a vibration device with asymmetric oscillations with the total driving force <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>F</mi> </mrow> <mrow> <mi>s</mi> <mi>u</mi> <mi>m</mi> </mrow> </msub> </mrow> </semantics></math> = 10 kN and the specified asymmetry coefficient <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>k</mi> </mrow> <mrow> <mi>a</mi> <mi>s</mi> </mrow> </msub> </mrow> </semantics></math> = 7.0. (<b>a</b>) is support reactions of each of the seven pairs of vibrators with the value <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>F</mi> </mrow> <mrow> <mi>s</mi> <mi>u</mi> <mi>m</mi> </mrow> </msub> </mrow> </semantics></math> = 1 kN and the initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mn>0</mn> </mrow> </semantics></math>; (<b>b</b>) is the sum of the support reactions of all seven pairs of vibrators with the initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mn>0</mn> </mrow> </semantics></math>; (<b>c</b>) is the support reactions of each of the seven pairs of vibrators with the initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mstyle scriptlevel="0" displaystyle="true"> <mfrac> <mrow> <mi>π</mi> </mrow> <mrow> <mn>2</mn> </mrow> </mfrac> </mstyle> <mrow> <mo>(</mo> <mi>k</mi> <mo>−</mo> <mn>1</mn> <mo>)</mo> </mrow> </mrow> </semantics></math>, (<b>d</b>) is the sum of the support reactions of all seven pairs of vibrators with the initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mstyle scriptlevel="0" displaystyle="true"> <mfrac> <mrow> <mi>π</mi> </mrow> <mrow> <mn>2</mn> </mrow> </mfrac> </mstyle> <mrow> <mo>(</mo> <mi>k</mi> <mo>−</mo> <mn>1</mn> <mo>)</mo> </mrow> </mrow> </semantics></math>.</p> Full article ">Figure 13 Cont.

<p>Calculation graphs of the magnitude of the driving forces of a vibration device with asymmetric oscillations with the total driving force <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>F</mi> </mrow> <mrow> <mi>s</mi> <mi>u</mi> <mi>m</mi> </mrow> </msub> </mrow> </semantics></math> = 10 kN and the specified asymmetry coefficient <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>k</mi> </mrow> <mrow> <mi>a</mi> <mi>s</mi> </mrow> </msub> </mrow> </semantics></math> = 7.0. (<b>a</b>) is support reactions of each of the seven pairs of vibrators with the value <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>F</mi> </mrow> <mrow> <mi>s</mi> <mi>u</mi> <mi>m</mi> </mrow> </msub> </mrow> </semantics></math> = 1 kN and the initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mn>0</mn> </mrow> </semantics></math>; (<b>b</b>) is the sum of the support reactions of all seven pairs of vibrators with the initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mn>0</mn> </mrow> </semantics></math>; (<b>c</b>) is the support reactions of each of the seven pairs of vibrators with the initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mstyle scriptlevel="0" displaystyle="true"> <mfrac> <mrow> <mi>π</mi> </mrow> <mrow> <mn>2</mn> </mrow> </mfrac> </mstyle> <mrow> <mo>(</mo> <mi>k</mi> <mo>−</mo> <mn>1</mn> <mo>)</mo> </mrow> </mrow> </semantics></math>, (<b>d</b>) is the sum of the support reactions of all seven pairs of vibrators with the initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mstyle scriptlevel="0" displaystyle="true"> <mfrac> <mrow> <mi>π</mi> </mrow> <mrow> <mn>2</mn> </mrow> </mfrac> </mstyle> <mrow> <mo>(</mo> <mi>k</mi> <mo>−</mo> <mn>1</mn> <mo>)</mo> </mrow> </mrow> </semantics></math>.</p> Full article ">Figure 14

<p>Graph of change in total driving force <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>F</mi> </mrow> <mrow> <mi>s</mi> <mi>u</mi> <mi>m</mi> </mrow> </msub> <mo>=</mo> <mi>f</mi> <mo>(</mo> <mi>t</mi> <mo>)</mo> </mrow> </semantics></math>.</p> Full article ">Figure 15

<p>(<b>a</b>) The test bench with synchronized pairs of imbalances for multi-stage production of asymmetric oscillations: 1 is a base, 2 is a body, 3 is a guide rod, 4 is the sliders, 5 is the imbalances, 6 is a driving force sensor. (<b>b</b>) A driving force magnitude recording sensor.</p> Full article ">

<p>Adding two (<span class="html-italic">F</span><sub>1</sub> and <span class="html-italic">F</span><sub>2</sub>) directed oscillations to obtain the total oscillation by initial conditions [<a href="#B31-vibration-08-00003" class="html-bibr">31</a>]. The asymmetry coefficient of the driving force is <math display="inline"><semantics> <mrow> <msub> <mrow> <msub> <mrow> <mi>k</mi> </mrow> <mrow> <mi>a</mi> <mi>s</mi> <mn>2</mn> </mrow> </msub> <mo>=</mo> <mi>k</mi> </mrow> <mrow> <mi>d</mi> <mn>2</mn> </mrow> </msub> <mo>=</mo> <mn>1.78</mn> </mrow> </semantics></math>, (<span class="html-italic">F<sub>sum</sub></span><sub>2</sub>).</p> Full article ">Figure 2

<p>Addition of three directional oscillations (<span class="html-italic">F</span><sub>1</sub> and <span class="html-italic">F</span><sub>2</sub>, <span class="html-italic">F</span><sub>3</sub>) to obtain a total oscillation (<span class="html-italic">F<sub>sum</sub></span><sub>3</sub>) with asymmetry of the driving force <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>k</mi> </mrow> <mrow> <mi>a</mi> <mi>s</mi> <mn>3</mn> </mrow> </msub> <mo>=</mo> <msub> <mrow> <mi>k</mi> </mrow> <mrow> <mi>d</mi> <mn>3</mn> </mrow> </msub> <mo>=</mo> <mn>3.0</mn> </mrow> </semantics></math>, [<a href="#B46-vibration-08-00003" class="html-bibr">46</a>].</p> Full article ">Figure 3

<p>Addition of four directional oscillations (<span class="html-italic">F</span><sub>1</sub> and <span class="html-italic">F</span><sub>2</sub>, <span class="html-italic">F</span><sub>3</sub>, <span class="html-italic">F</span><sub>4</sub>) to obtain a total oscillation with asymmetry of the driving force <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>k</mi> </mrow> <mrow> <mi>d</mi> </mrow> </msub> <mo>=</mo> <mn>4.0</mn> </mrow> </semantics></math>, (<math display="inline"><semantics> <mrow> <msub> <mrow> <msub> <mrow> <mi>k</mi> </mrow> <mrow> <mi>a</mi> <mi>s</mi> <mn>4</mn> </mrow> </msub> <mo>=</mo> <mi>k</mi> </mrow> <mrow> <mi>d</mi> <mn>4</mn> </mrow> </msub> <mo>=</mo> <mn>3.89</mn> </mrow> </semantics></math>, (<math display="inline"><semantics> <mrow> <msub> <mrow> <mi>F</mi> </mrow> <mrow> <mi>s</mi> <mi>u</mi> <mi>m</mi> <mn>4</mn> </mrow> </msub> </mrow> </semantics></math>)).</p> Full article ">Figure 4

<p>Graph of the change in the asymmetry coefficient (<math display="inline"><semantics> <mrow> <msub> <mrow> <mi>k</mi> </mrow> <mrow> <mi>a</mi> <mi>s</mi> <mi>n</mi> </mrow> </msub> </mrow> </semantics></math>) of the total driving force of the vibration device, formed on the basis of the terms of the Fourier series of the function <math display="inline"><semantics> <mrow> <mo>=</mo> <msup> <mrow> <mi>c</mi> <mi>o</mi> <mi>s</mi> </mrow> <mrow> <mn>12</mn> </mrow> </msup> <mstyle scriptlevel="0" displaystyle="true"> <mfrac> <mrow> <mi>x</mi> </mrow> <mrow> <mn>2</mn> </mrow> </mfrac> </mstyle> </mrow> </semantics></math> for the first six terms (<span class="html-italic">n</span> = 1…6).</p> Full article ">Figure 5

<p>A diagram of a vibration mechanism consisting of <span class="html-italic">n</span> pairs of unbalanced vibrators, each pair of which forms a vibration block, a stage that generates directed oscillations.</p> Full article ">Figure 6

<p>Support reactions of each of the seven pairs of vibrators with the value <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>a</mi> </mrow> <mrow> <mi>k</mi> </mrow> </msub> <mo>=</mo> <mn>1.0</mn> </mrow> </semantics></math> and initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mn>0</mn> </mrow> </semantics></math>.</p> Full article ">Figure 7

<p>The sum of support reactions of all seven pairs of vibrators with the value <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>a</mi> </mrow> <mrow> <mi>k</mi> </mrow> </msub> <mo>=</mo> <mn>1.0</mn> </mrow> </semantics></math> and initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mn>0</mn> </mrow> </semantics></math>.</p> Full article ">Figure 8

<p>Support reactions of each of the seven pairs of vibrators with coefficients <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>a</mi> </mrow> <mrow> <mi>k</mi> <mi>i</mi> </mrow> </msub> <mo>=</mo> <mn>1.0</mn> </mrow> </semantics></math> and initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mstyle scriptlevel="0" displaystyle="true"> <mfrac> <mrow> <mi>π</mi> </mrow> <mrow> <mn>2</mn> </mrow> </mfrac> </mstyle> <mrow> <mo>(</mo> <mi>k</mi> <mo>−</mo> <mn>1</mn> <mo>)</mo> </mrow> </mrow> </semantics></math>, calculated using Equation (26).</p> Full article ">Figure 9

<p>The sum of support reactions of all seven pairs of vibrators with coefficients <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>a</mi> </mrow> <mrow> <mi>k</mi> </mrow> </msub> <mo>=</mo> <mn>1.0</mn> </mrow> </semantics></math> and initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mstyle scriptlevel="0" displaystyle="true"> <mfrac> <mrow> <mi>π</mi> </mrow> <mrow> <mn>2</mn> </mrow> </mfrac> </mstyle> <mrow> <mo>(</mo> <mi>k</mi> <mo>−</mo> <mn>1</mn> <mo>)</mo> </mrow> </mrow> </semantics></math>, calculated using Equation (26).</p> Full article ">Figure 10

<p>Fejer kernel, (<b>a</b>) is for N = 7, (<b>b</b>) is for several Fejer kernels [<a href="#B39-vibration-08-00003" class="html-bibr">39</a>,<a href="#B40-vibration-08-00003" class="html-bibr">40</a>,<a href="#B41-vibration-08-00003" class="html-bibr">41</a>].</p> Full article ">Figure 11

<p>Calculation of simplexes in the process of determining the optimal values of parameters <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>a</mi> </mrow> <mrow> <mn>1</mn> </mrow> </msub> </mrow> </semantics></math> and <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>a</mi> </mrow> <mrow> <mn>2</mn> </mrow> </msub> </mrow> </semantics></math>.</p> Full article ">Figure 12

<p>Values of parameters at the vertices of simplexes and the corresponding values of the dynamic coefficient <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>k</mi> </mrow> <mrow> <mi>d</mi> </mrow> </msub> </mrow> </semantics></math>.</p> Full article ">Figure 13

<p>Calculation graphs of the magnitude of the driving forces of a vibration device with asymmetric oscillations with the total driving force <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>F</mi> </mrow> <mrow> <mi>s</mi> <mi>u</mi> <mi>m</mi> </mrow> </msub> </mrow> </semantics></math> = 10 kN and the specified asymmetry coefficient <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>k</mi> </mrow> <mrow> <mi>a</mi> <mi>s</mi> </mrow> </msub> </mrow> </semantics></math> = 7.0. (<b>a</b>) is support reactions of each of the seven pairs of vibrators with the value <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>F</mi> </mrow> <mrow> <mi>s</mi> <mi>u</mi> <mi>m</mi> </mrow> </msub> </mrow> </semantics></math> = 1 kN and the initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mn>0</mn> </mrow> </semantics></math>; (<b>b</b>) is the sum of the support reactions of all seven pairs of vibrators with the initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mn>0</mn> </mrow> </semantics></math>; (<b>c</b>) is the support reactions of each of the seven pairs of vibrators with the initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mstyle scriptlevel="0" displaystyle="true"> <mfrac> <mrow> <mi>π</mi> </mrow> <mrow> <mn>2</mn> </mrow> </mfrac> </mstyle> <mrow> <mo>(</mo> <mi>k</mi> <mo>−</mo> <mn>1</mn> <mo>)</mo> </mrow> </mrow> </semantics></math>, (<b>d</b>) is the sum of the support reactions of all seven pairs of vibrators with the initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mstyle scriptlevel="0" displaystyle="true"> <mfrac> <mrow> <mi>π</mi> </mrow> <mrow> <mn>2</mn> </mrow> </mfrac> </mstyle> <mrow> <mo>(</mo> <mi>k</mi> <mo>−</mo> <mn>1</mn> <mo>)</mo> </mrow> </mrow> </semantics></math>.</p> Full article ">Figure 13 Cont.

<p>Calculation graphs of the magnitude of the driving forces of a vibration device with asymmetric oscillations with the total driving force <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>F</mi> </mrow> <mrow> <mi>s</mi> <mi>u</mi> <mi>m</mi> </mrow> </msub> </mrow> </semantics></math> = 10 kN and the specified asymmetry coefficient <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>k</mi> </mrow> <mrow> <mi>a</mi> <mi>s</mi> </mrow> </msub> </mrow> </semantics></math> = 7.0. (<b>a</b>) is support reactions of each of the seven pairs of vibrators with the value <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>F</mi> </mrow> <mrow> <mi>s</mi> <mi>u</mi> <mi>m</mi> </mrow> </msub> </mrow> </semantics></math> = 1 kN and the initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mn>0</mn> </mrow> </semantics></math>; (<b>b</b>) is the sum of the support reactions of all seven pairs of vibrators with the initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mn>0</mn> </mrow> </semantics></math>; (<b>c</b>) is the support reactions of each of the seven pairs of vibrators with the initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mstyle scriptlevel="0" displaystyle="true"> <mfrac> <mrow> <mi>π</mi> </mrow> <mrow> <mn>2</mn> </mrow> </mfrac> </mstyle> <mrow> <mo>(</mo> <mi>k</mi> <mo>−</mo> <mn>1</mn> <mo>)</mo> </mrow> </mrow> </semantics></math>, (<b>d</b>) is the sum of the support reactions of all seven pairs of vibrators with the initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mstyle scriptlevel="0" displaystyle="true"> <mfrac> <mrow> <mi>π</mi> </mrow> <mrow> <mn>2</mn> </mrow> </mfrac> </mstyle> <mrow> <mo>(</mo> <mi>k</mi> <mo>−</mo> <mn>1</mn> <mo>)</mo> </mrow> </mrow> </semantics></math>.</p> Full article ">Figure 13 Cont.

<p>Calculation graphs of the magnitude of the driving forces of a vibration device with asymmetric oscillations with the total driving force <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>F</mi> </mrow> <mrow> <mi>s</mi> <mi>u</mi> <mi>m</mi> </mrow> </msub> </mrow> </semantics></math> = 10 kN and the specified asymmetry coefficient <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>k</mi> </mrow> <mrow> <mi>a</mi> <mi>s</mi> </mrow> </msub> </mrow> </semantics></math> = 7.0. (<b>a</b>) is support reactions of each of the seven pairs of vibrators with the value <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>F</mi> </mrow> <mrow> <mi>s</mi> <mi>u</mi> <mi>m</mi> </mrow> </msub> </mrow> </semantics></math> = 1 kN and the initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mn>0</mn> </mrow> </semantics></math>; (<b>b</b>) is the sum of the support reactions of all seven pairs of vibrators with the initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mn>0</mn> </mrow> </semantics></math>; (<b>c</b>) is the support reactions of each of the seven pairs of vibrators with the initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mstyle scriptlevel="0" displaystyle="true"> <mfrac> <mrow> <mi>π</mi> </mrow> <mrow> <mn>2</mn> </mrow> </mfrac> </mstyle> <mrow> <mo>(</mo> <mi>k</mi> <mo>−</mo> <mn>1</mn> <mo>)</mo> </mrow> </mrow> </semantics></math>, (<b>d</b>) is the sum of the support reactions of all seven pairs of vibrators with the initial phases <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>φ</mi> </mrow> <mrow> <mi>k</mi> <mn>0</mn> </mrow> </msub> <mo>=</mo> <mstyle scriptlevel="0" displaystyle="true"> <mfrac> <mrow> <mi>π</mi> </mrow> <mrow> <mn>2</mn> </mrow> </mfrac> </mstyle> <mrow> <mo>(</mo> <mi>k</mi> <mo>−</mo> <mn>1</mn> <mo>)</mo> </mrow> </mrow> </semantics></math>.</p> Full article ">Figure 14

<p>Graph of change in total driving force <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>F</mi> </mrow> <mrow> <mi>s</mi> <mi>u</mi> <mi>m</mi> </mrow> </msub> <mo>=</mo> <mi>f</mi> <mo>(</mo> <mi>t</mi> <mo>)</mo> </mrow> </semantics></math>.</p> Full article ">Figure 15

<p>(<b>a</b>) The test bench with synchronized pairs of imbalances for multi-stage production of asymmetric oscillations: 1 is a base, 2 is a body, 3 is a guide rod, 4 is the sliders, 5 is the imbalances, 6 is a driving force sensor. (<b>b</b>) A driving force magnitude recording sensor.</p> Full article ">

Open AccessArticle

Application of Homogenization Method in Free Vibration of Multi-Material Auxetic Metamaterials

by

Kadir Gunaydin, Orhan Gülcan and Aykut Tamer

Vibration 2025, 8(1), 2; https://doi.org/10.3390/vibration8010002 - 13 Jan 2025

Abstract

►▼

Show Figures

Different additive manufacturing modalities enable the production of multi-material components which can be used in a wide range of industrial applications. The prediction of the mechanical properties of these components via finite element modelling rather than through testing is critical in terms of

[...] Read more.

Different additive manufacturing modalities enable the production of multi-material components which can be used in a wide range of industrial applications. The prediction of the mechanical properties of these components via finite element modelling rather than through testing is critical in terms of cost and time. However, due to the higher computational time spent on the modelling of lattice structures, different methods have been investigated to accurately predict mechanical properties. For this purpose, this study proposes the use of a homogenization method in the two most common types of multi-material lattices: honeycomb and re-entrant auxetics. Modal analyses were performed, and the first six mode shapes were extracted from explicit and implicit models. The results were compared in terms of mode shapes and natural frequencies. The results showed that homogenization can be successfully applied to multi-material honeycomb and re-entrant auxetic lattices without compromising the accuracy. It was shown that the implicit models predict the natural frequencies with an error range of less than 6.5% when compared with the explicit models in all of the mode shapes for both honeycomb and re-entrant auxetic lattices. The Modal Assurance Criteria, which is an indication of the degree of similarity between the mode shapes of explicit and implicit models, was found to be higher than 0.996, indicating very high similarity.

Full article

Figure 1

Figure 1

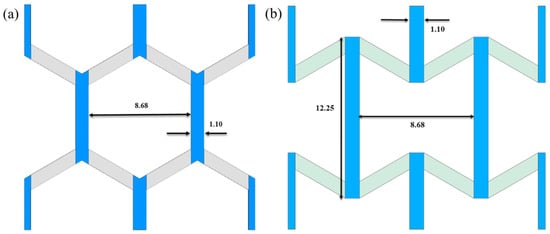

<p>Unit cell topologies: (<b>a</b>) honeycomb, (<b>b</b>) re-entrant. Units are in mm.</p> Full article ">Figure 2

<p>Elastic modulus convergence plot in z direction for honeycomb lattice structure.</p> Full article ">Figure 3

<p>Test articles: (<b>a</b>) honeycomb, (<b>b</b>) re-entrant.</p> Full article ">Figure 4

<p>Meshed unit cells: (<b>a</b>) honeycomb, (<b>b</b>) re-entrant.</p> Full article ">Figure 5

<p>Meshed lattice structures: (<b>a</b>) honeycomb explicit, (<b>b</b>) honeycomb implicit, (<b>c</b>) re-entrant explicit, (<b>d</b>) re-entrant implicit.</p> Full article ">

<p>Unit cell topologies: (<b>a</b>) honeycomb, (<b>b</b>) re-entrant. Units are in mm.</p> Full article ">Figure 2

<p>Elastic modulus convergence plot in z direction for honeycomb lattice structure.</p> Full article ">Figure 3

<p>Test articles: (<b>a</b>) honeycomb, (<b>b</b>) re-entrant.</p> Full article ">Figure 4

<p>Meshed unit cells: (<b>a</b>) honeycomb, (<b>b</b>) re-entrant.</p> Full article ">Figure 5

<p>Meshed lattice structures: (<b>a</b>) honeycomb explicit, (<b>b</b>) honeycomb implicit, (<b>c</b>) re-entrant explicit, (<b>d</b>) re-entrant implicit.</p> Full article ">

Open AccessArticle

Parameter Estimation of Nonlinear Structural Systems Using Bayesian Filtering Methods

by

Kalil Erazo

Vibration 2025, 8(1), 1; https://doi.org/10.3390/vibration8010001 - 31 Dec 2024

Abstract

►▼

Show Figures

This paper examines the performance of Bayesian filtering system identification in the context of nonlinear structural and mechanical systems. The objective is to assess the accuracy and limitations of the four most well-established filtering-based parameter estimation methods: the extended Kalman filter, the unscented

[...] Read more.

This paper examines the performance of Bayesian filtering system identification in the context of nonlinear structural and mechanical systems. The objective is to assess the accuracy and limitations of the four most well-established filtering-based parameter estimation methods: the extended Kalman filter, the unscented Kalman filter, the ensemble Kalman filter, and the particle filter. The four methods are applied to estimate the parameters and the response of benchmark dynamical systems used in structural mechanics, including a Duffing oscillator, a hysteretic Bouc–Wen oscillator, and a hysteretic Bouc–Wen chain system. Based on the performance, accuracy, and computational efficiency of the methods under different operating conditions, it is concluded that the unscented Kalman filter is the most effective filtering system identification method for the systems considered, with the other filters showing large estimation errors or divergence, high computational cost, and/or curse of dimensionality as the dimension of the system and the number of uncertain parameters increased.

Full article

Figure 1

Figure 1

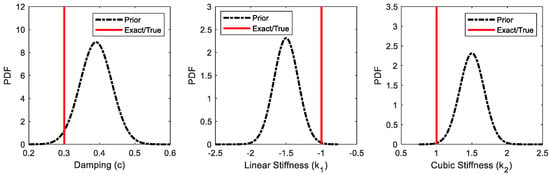

<p>Parameters prior distributions for the Duffing oscillator example (in SI units).</p> Full article ">Figure 2

<p>Damping coefficient (<math display="inline"><semantics> <mrow> <mi mathvariant="normal">c</mi> <mo>)</mo> </mrow> </semantics></math> estimates (in Ns/m).</p> Full article ">Figure 3

<p>Linear stiffness coefficient (<math display="inline"><semantics> <mrow> <msub> <mrow> <mi mathvariant="normal">k</mi> </mrow> <mrow> <mn>1</mn> </mrow> </msub> </mrow> </semantics></math>) estimates (in N/m).</p> Full article ">Figure 4

<p>Cubic stiffness coefficient (<math display="inline"><semantics> <mrow> <msub> <mrow> <mi mathvariant="normal">k</mi> </mrow> <mrow> <mn>2</mn> </mrow> </msub> </mrow> </semantics></math>) estimates (in N/m<sup>3</sup>).</p> Full article ">Figure 5

<p>Oscillator displacement estimates (in m).</p> Full article ">Figure 6

<p>Oscillator velocity estimates (in m/s).</p> Full article ">Figure 7

<p>Parameters prior distributions for the hysteretic oscillator example (in SI units).</p> Full article ">Figure 8

<p>Hysteresis shape parameter (<math display="inline"><semantics> <mrow> <mi>β</mi> </mrow> </semantics></math>) estimates (non-dimensional).</p> Full article ">Figure 9

<p>Yielding displacement parameter (<math display="inline"><semantics> <mrow> <msub> <mrow> <mi mathvariant="normal">D</mi> </mrow> <mrow> <mi mathvariant="normal">y</mi> </mrow> </msub> </mrow> </semantics></math>) estimates (in m).</p> Full article ">Figure 10

<p>Elastic-to-Plastic transition parameter (<math display="inline"><semantics> <mrow> <mi>ν</mi> </mrow> </semantics></math>) estimates (non-dimensional).</p> Full article ">Figure 11

<p>Oscillator displacement estimates (in m).</p> Full article ">Figure 12

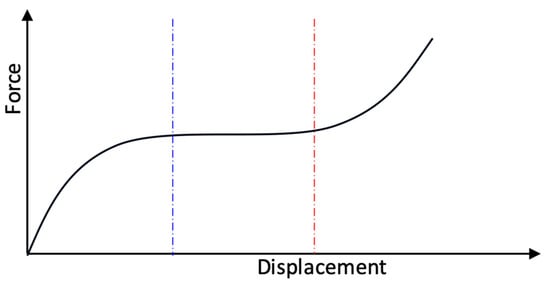

<p>Oscillator force–displacement hysteretic response estimates (in SI units).</p> Full article ">Figure 13

<p>Hysteretic five-degrees-of-freedom chain system.</p> Full article ">Figure 14

<p>Hysteresis parameter (<math display="inline"><semantics> <mrow> <mi>β</mi> </mrow> </semantics></math>) mean estimates for all degrees of freedom (non-dimensional).</p> Full article ">Figure 15

<p>Yielding displacement parameter (<math display="inline"><semantics> <mrow> <msub> <mrow> <mi mathvariant="normal">D</mi> </mrow> <mrow> <mi mathvariant="normal">y</mi> </mrow> </msub> </mrow> </semantics></math>) mean estimates for all degrees of freedom (in m).</p> Full article ">Figure 16

<p>Elastic-to-Plastic transition parameter (<math display="inline"><semantics> <mrow> <mi>ν</mi> </mrow> </semantics></math>) mean estimates for all degrees of freedom (non-dimensional).</p> Full article ">

<p>Parameters prior distributions for the Duffing oscillator example (in SI units).</p> Full article ">Figure 2

<p>Damping coefficient (<math display="inline"><semantics> <mrow> <mi mathvariant="normal">c</mi> <mo>)</mo> </mrow> </semantics></math> estimates (in Ns/m).</p> Full article ">Figure 3

<p>Linear stiffness coefficient (<math display="inline"><semantics> <mrow> <msub> <mrow> <mi mathvariant="normal">k</mi> </mrow> <mrow> <mn>1</mn> </mrow> </msub> </mrow> </semantics></math>) estimates (in N/m).</p> Full article ">Figure 4

<p>Cubic stiffness coefficient (<math display="inline"><semantics> <mrow> <msub> <mrow> <mi mathvariant="normal">k</mi> </mrow> <mrow> <mn>2</mn> </mrow> </msub> </mrow> </semantics></math>) estimates (in N/m<sup>3</sup>).</p> Full article ">Figure 5

<p>Oscillator displacement estimates (in m).</p> Full article ">Figure 6

<p>Oscillator velocity estimates (in m/s).</p> Full article ">Figure 7

<p>Parameters prior distributions for the hysteretic oscillator example (in SI units).</p> Full article ">Figure 8

<p>Hysteresis shape parameter (<math display="inline"><semantics> <mrow> <mi>β</mi> </mrow> </semantics></math>) estimates (non-dimensional).</p> Full article ">Figure 9

<p>Yielding displacement parameter (<math display="inline"><semantics> <mrow> <msub> <mrow> <mi mathvariant="normal">D</mi> </mrow> <mrow> <mi mathvariant="normal">y</mi> </mrow> </msub> </mrow> </semantics></math>) estimates (in m).</p> Full article ">Figure 10

<p>Elastic-to-Plastic transition parameter (<math display="inline"><semantics> <mrow> <mi>ν</mi> </mrow> </semantics></math>) estimates (non-dimensional).</p> Full article ">Figure 11

<p>Oscillator displacement estimates (in m).</p> Full article ">Figure 12

<p>Oscillator force–displacement hysteretic response estimates (in SI units).</p> Full article ">Figure 13

<p>Hysteretic five-degrees-of-freedom chain system.</p> Full article ">Figure 14

<p>Hysteresis parameter (<math display="inline"><semantics> <mrow> <mi>β</mi> </mrow> </semantics></math>) mean estimates for all degrees of freedom (non-dimensional).</p> Full article ">Figure 15

<p>Yielding displacement parameter (<math display="inline"><semantics> <mrow> <msub> <mrow> <mi mathvariant="normal">D</mi> </mrow> <mrow> <mi mathvariant="normal">y</mi> </mrow> </msub> </mrow> </semantics></math>) mean estimates for all degrees of freedom (in m).</p> Full article ">Figure 16

<p>Elastic-to-Plastic transition parameter (<math display="inline"><semantics> <mrow> <mi>ν</mi> </mrow> </semantics></math>) mean estimates for all degrees of freedom (non-dimensional).</p> Full article ">

Open AccessArticle

Mitigating Motion Sickness by Anticipatory Cues

by

Anna J. C. Reuten, Jelte E. Bos, Marieke H. Martens, Jessica Rausch and Jeroen B. J. Smeets

Vibration 2024, 7(4), 1266-1278; https://doi.org/10.3390/vibration7040065 - 21 Dec 2024

Abstract

►▼

Show Figures

Car passengers suffer much more from motion sickness compared to car drivers, presumably because drivers can better anticipate the car’s motions. Visual and auditory cues that announce upcoming motions have been demonstrated to mitigate motion sickness. In automated vehicles, vibrotactile cues might be

[...] Read more.

Car passengers suffer much more from motion sickness compared to car drivers, presumably because drivers can better anticipate the car’s motions. Visual and auditory cues that announce upcoming motions have been demonstrated to mitigate motion sickness. In automated vehicles, vibrotactile cues might be more desirable. However, prior studies provided mixed evidence regarding their effectiveness. In this study, we directly compared the effectiveness of anticipatory auditory and vibrotactile cues. We determined their effectiveness by examining self-reported motion sickness from anticipatory sessions with auditory or vibrotactile cues announcing the onset and direction of upcoming motion relative to a control session. Our preregistered analysis did not show a significant difference in mitigation between the cues but also no significant overall effect. As this lack of an effect may be due to limited statistical power, we performed an internal meta-analysis. This analysis demonstrated a small overall effect of anticipatory cues. We conclude that it is worthwhile to investigate how their effectiveness can be enhanced.

Full article

Figure 1

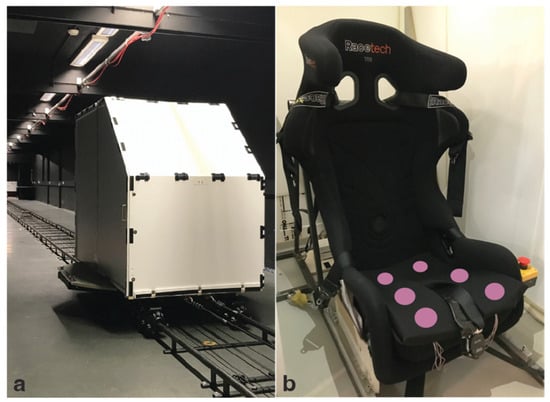

Figure 1

<p>Experimental apparatus. (<b>a</b>) The cabin of the linear sled offered an enclosed space that removed airflow and visual cues on motion. (<b>b</b>) Interior view of the cabin. The purple dots indicate the positions of six actuators used to present the vibrotactile cues. Replicated from Reuten et al. [<a href="#B21-vibration-07-00065" class="html-bibr">21</a>].</p> Full article ">Figure 2

<p>Presentation of the cues in relation to the motion stimulus. Bluish colors indicate the auditory sessions and reddish colors indicate the vibrotactile sessions. Filled bars represent cues indicating a forward motion; open bars represent cues indicating a backward motion. In the anticipatory sessions (<math display="inline"><semantics> <mrow> <mi>A</mi> </mrow> </semantics></math>, darker colors), the cues were presented 1 s in advance of motion onset and always indicated the initial motion direction. In the control sessions (<math display="inline"><semantics> <mrow> <mi>C</mi> </mrow> </semantics></math>, lighter colors), the cues were presented 2 to 6.5 s after motion onset and independent of the initial motion direction.</p> Full article ">Figure 3

<p>(<b>a</b>) The development of MISC scores averaged across participants for each of the four sessions. After a participant reaches the stop-criterion, they no longer contribute to the average of that session, resulting in a decrease in the average MISC. We excluded data on those time points in the anticipatory sessions when a participant reached the stop-criterion in the corresponding control session (similar to our measure <math display="inline"><semantics> <mrow> <mi>R</mi> </mrow> </semantics></math>). The inset displays the number of participants reaching the stop-criterion per time point. (<b>b</b>) The reduction values for individual participants (<math display="inline"><semantics> <mrow> <msub> <mrow> <mover accent="true"> <mrow> <mi>R</mi> </mrow> <mo>¯</mo> </mover> </mrow> <mrow> <mi>i</mi> </mrow> </msub> </mrow> </semantics></math>) calculated for the auditory (blue) and vibrotactile (red) anticipatory sessions. The error bars are 95% confidence intervals. (<b>c</b>) The overall weighted average of the reduction (<math display="inline"><semantics> <mrow> <mover accent="true"> <mrow> <mi>R</mi> </mrow> <mo>¯</mo> </mover> </mrow> </semantics></math>) in motion sickness generated by each anticipatory cue. The error bars are 95% one-sided confidence intervals (coherent with our one-sided analysis). The size of the data points in panels b and c reflects the sum of MISC scores underlying the data. The horizontal lines at zero correspond to no reduction.</p> Full article ">Figure 4

<p>Results of the user experience questionnaire. Participants indicated (<b>a</b>) when they thought the cues were presented, (<b>b</b>) how often they perceived the cues, (<b>c</b>) how they evaluated the cues along a range of user dimensions (error bars indicate standard deviations), (<b>d</b>) which cue helped to mitigate motion sickness, (<b>e</b>) which cue they preferred to announce upcoming motions, and (<b>f</b>) if they would want to use the cue they preferred in their (automated) car. For the questions in panels a, d and e, the participants were given additional answer options that none of them selected.</p> Full article ">Figure 5

<p>Results of an internal meta-analysis with the reduction values calculated for each participant (<math display="inline"><semantics> <mrow> <msub> <mrow> <mover accent="true"> <mrow> <mi>R</mi> </mrow> <mo>¯</mo> </mover> </mrow> <mrow> <mi>i</mi> </mrow> </msub> </mrow> </semantics></math>) in three comparable studies on anticipatory cueing (Kuiper et al. [<a href="#B9-vibration-07-00065" class="html-bibr">9</a>], Reuten et al. [<a href="#B21-vibration-07-00065" class="html-bibr">21</a>], and the current study). The dashed line represents the overall reduction <math display="inline"><semantics> <mrow> <mover accent="true"> <mrow> <mi>R</mi> </mrow> <mo>¯</mo> </mover> </mrow> </semantics></math> across all studies. Further details as in <a href="#vibration-07-00065-f003" class="html-fig">Figure 3</a>.</p> Full article ">Figure 6

<p>Exploratory analyses to investigate whether the between-participant variability in <a href="#vibration-07-00065-f003" class="html-fig">Figure 3</a>b and <a href="#vibration-07-00065-f005" class="html-fig">Figure 5</a> is characteristic of idiosyncratic benefits or the result of uncontrollable variability. (<b>a</b>) The reduction values for a sham comparison (the auditory control relative to the vibrotactile control session), for which one expects <math display="inline"><semantics> <mrow> <msub> <mrow> <mover accent="true"> <mrow> <mi>R</mi> </mrow> <mo>¯</mo> </mover> </mrow> <mrow> <mi>i</mi> </mrow> </msub> </mrow> </semantics></math> = 0. The dashed line represents the overall reduction <math display="inline"><semantics> <mrow> <mover accent="true"> <mrow> <mi>R</mi> </mrow> <mo>¯</mo> </mover> </mrow> </semantics></math>, which is indeed close to zero. Further details as in <a href="#vibration-07-00065-f003" class="html-fig">Figure 3</a>b. (<b>b</b>) The <math display="inline"><semantics> <mrow> <msub> <mrow> <mover accent="true"> <mrow> <mi>R</mi> </mrow> <mo>¯</mo> </mover> </mrow> <mrow> <mi>i</mi> </mrow> </msub> </mrow> </semantics></math> values for the anticipatory auditory session are plotted against those in the anticipatory vibrotactile session. In this panel, the size of the data points is determined by the square root of the product of auditory and vibrotactile <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>w</mi> </mrow> <mrow> <mi>i</mi> </mrow> </msub> </mrow> </semantics></math> values. The large between-participant variability in the sham comparison in Panel A and the absence of a correlation in Panel B suggest that the differences in <math display="inline"><semantics> <mrow> <msub> <mrow> <mover accent="true"> <mrow> <mi>R</mi> </mrow> <mo>¯</mo> </mover> </mrow> <mrow> <mi>i</mi> </mrow> </msub> </mrow> </semantics></math> between participants in <a href="#vibration-07-00065-f003" class="html-fig">Figure 3</a>b and <a href="#vibration-07-00065-f005" class="html-fig">Figure 5</a> are more likely to reflect uncontrollable variability.</p> Full article ">

<p>Experimental apparatus. (<b>a</b>) The cabin of the linear sled offered an enclosed space that removed airflow and visual cues on motion. (<b>b</b>) Interior view of the cabin. The purple dots indicate the positions of six actuators used to present the vibrotactile cues. Replicated from Reuten et al. [<a href="#B21-vibration-07-00065" class="html-bibr">21</a>].</p> Full article ">Figure 2

<p>Presentation of the cues in relation to the motion stimulus. Bluish colors indicate the auditory sessions and reddish colors indicate the vibrotactile sessions. Filled bars represent cues indicating a forward motion; open bars represent cues indicating a backward motion. In the anticipatory sessions (<math display="inline"><semantics> <mrow> <mi>A</mi> </mrow> </semantics></math>, darker colors), the cues were presented 1 s in advance of motion onset and always indicated the initial motion direction. In the control sessions (<math display="inline"><semantics> <mrow> <mi>C</mi> </mrow> </semantics></math>, lighter colors), the cues were presented 2 to 6.5 s after motion onset and independent of the initial motion direction.</p> Full article ">Figure 3

<p>(<b>a</b>) The development of MISC scores averaged across participants for each of the four sessions. After a participant reaches the stop-criterion, they no longer contribute to the average of that session, resulting in a decrease in the average MISC. We excluded data on those time points in the anticipatory sessions when a participant reached the stop-criterion in the corresponding control session (similar to our measure <math display="inline"><semantics> <mrow> <mi>R</mi> </mrow> </semantics></math>). The inset displays the number of participants reaching the stop-criterion per time point. (<b>b</b>) The reduction values for individual participants (<math display="inline"><semantics> <mrow> <msub> <mrow> <mover accent="true"> <mrow> <mi>R</mi> </mrow> <mo>¯</mo> </mover> </mrow> <mrow> <mi>i</mi> </mrow> </msub> </mrow> </semantics></math>) calculated for the auditory (blue) and vibrotactile (red) anticipatory sessions. The error bars are 95% confidence intervals. (<b>c</b>) The overall weighted average of the reduction (<math display="inline"><semantics> <mrow> <mover accent="true"> <mrow> <mi>R</mi> </mrow> <mo>¯</mo> </mover> </mrow> </semantics></math>) in motion sickness generated by each anticipatory cue. The error bars are 95% one-sided confidence intervals (coherent with our one-sided analysis). The size of the data points in panels b and c reflects the sum of MISC scores underlying the data. The horizontal lines at zero correspond to no reduction.</p> Full article ">Figure 4

<p>Results of the user experience questionnaire. Participants indicated (<b>a</b>) when they thought the cues were presented, (<b>b</b>) how often they perceived the cues, (<b>c</b>) how they evaluated the cues along a range of user dimensions (error bars indicate standard deviations), (<b>d</b>) which cue helped to mitigate motion sickness, (<b>e</b>) which cue they preferred to announce upcoming motions, and (<b>f</b>) if they would want to use the cue they preferred in their (automated) car. For the questions in panels a, d and e, the participants were given additional answer options that none of them selected.</p> Full article ">Figure 5

<p>Results of an internal meta-analysis with the reduction values calculated for each participant (<math display="inline"><semantics> <mrow> <msub> <mrow> <mover accent="true"> <mrow> <mi>R</mi> </mrow> <mo>¯</mo> </mover> </mrow> <mrow> <mi>i</mi> </mrow> </msub> </mrow> </semantics></math>) in three comparable studies on anticipatory cueing (Kuiper et al. [<a href="#B9-vibration-07-00065" class="html-bibr">9</a>], Reuten et al. [<a href="#B21-vibration-07-00065" class="html-bibr">21</a>], and the current study). The dashed line represents the overall reduction <math display="inline"><semantics> <mrow> <mover accent="true"> <mrow> <mi>R</mi> </mrow> <mo>¯</mo> </mover> </mrow> </semantics></math> across all studies. Further details as in <a href="#vibration-07-00065-f003" class="html-fig">Figure 3</a>.</p> Full article ">Figure 6

<p>Exploratory analyses to investigate whether the between-participant variability in <a href="#vibration-07-00065-f003" class="html-fig">Figure 3</a>b and <a href="#vibration-07-00065-f005" class="html-fig">Figure 5</a> is characteristic of idiosyncratic benefits or the result of uncontrollable variability. (<b>a</b>) The reduction values for a sham comparison (the auditory control relative to the vibrotactile control session), for which one expects <math display="inline"><semantics> <mrow> <msub> <mrow> <mover accent="true"> <mrow> <mi>R</mi> </mrow> <mo>¯</mo> </mover> </mrow> <mrow> <mi>i</mi> </mrow> </msub> </mrow> </semantics></math> = 0. The dashed line represents the overall reduction <math display="inline"><semantics> <mrow> <mover accent="true"> <mrow> <mi>R</mi> </mrow> <mo>¯</mo> </mover> </mrow> </semantics></math>, which is indeed close to zero. Further details as in <a href="#vibration-07-00065-f003" class="html-fig">Figure 3</a>b. (<b>b</b>) The <math display="inline"><semantics> <mrow> <msub> <mrow> <mover accent="true"> <mrow> <mi>R</mi> </mrow> <mo>¯</mo> </mover> </mrow> <mrow> <mi>i</mi> </mrow> </msub> </mrow> </semantics></math> values for the anticipatory auditory session are plotted against those in the anticipatory vibrotactile session. In this panel, the size of the data points is determined by the square root of the product of auditory and vibrotactile <math display="inline"><semantics> <mrow> <msub> <mrow> <mi>w</mi> </mrow> <mrow> <mi>i</mi> </mrow> </msub> </mrow> </semantics></math> values. The large between-participant variability in the sham comparison in Panel A and the absence of a correlation in Panel B suggest that the differences in <math display="inline"><semantics> <mrow> <msub> <mrow> <mover accent="true"> <mrow> <mi>R</mi> </mrow> <mo>¯</mo> </mover> </mrow> <mrow> <mi>i</mi> </mrow> </msub> </mrow> </semantics></math> between participants in <a href="#vibration-07-00065-f003" class="html-fig">Figure 3</a>b and <a href="#vibration-07-00065-f005" class="html-fig">Figure 5</a> are more likely to reflect uncontrollable variability.</p> Full article ">

Open AccessArticle

Stress Distribution and Transverse Vibration of Flywheel Within Linear Elastic Range

by

Desejo Filipeson Sozinando, Kgotso Koketso Leema, Vhahangwele Colleen Sigonde, Bernard Xavier Tchomeni and Alfayo Anyika Alugongo

Vibration 2024, 7(4), 1248-1265; https://doi.org/10.3390/vibration7040064 - 13 Dec 2024

Abstract

►▼

Show Figures

Flywheels have been largely used in rotating machine engines to save inertial energy and to limit speed fluctuations. A stress distribution problem is created due to the centrifugal forces that are formed when the flywheel is spinning around, which leads to different levels

[...] Read more.

Flywheels have been largely used in rotating machine engines to save inertial energy and to limit speed fluctuations. A stress distribution problem is created due to the centrifugal forces that are formed when the flywheel is spinning around, which leads to different levels of pressure and decompression inside its structure. Lack of balance leads to high energy losses through various mechanisms, which deteriorate both the flywheel’s expectancy and their ability to rotate at high speeds. Deviation in the design of flywheels from their optimum performance can cause instability issues and even a catastrophic failure during operation. This paper aims to analytically examine the stress distribution of radial and tangential directions along the flywheel structure within a linear elastic range. The eigenvalues and eigenvectors, which are representative of free vibrational features, were extracted by applying finite element analysis (FEA). Natural frequencies and their corresponding vibrating mode shapes and mass participation factors were identified. Furthermore, Kirchhoff–Love plate theory was employed to model the transverse vibration of the system. A general solution for the radial component of the equation of flywheel motion was derived with the help of the Bessel function. The results show certain modes of vibration identified as particularly influential in specific directions. Advanced time-frequency analysis techniques, including but not limited to continuous wavelet transform (CWT) and Hilbert–Huang transform (HHT), were applied to extract transverse vibration features of the flywheel system. It was also found that using CWT, low-frequency vibrations contribute to the majority of the energy in the extracted signal spectrum, while HHT exposes the high-frequency components of vibration that may cause significant structural damage if not addressed in time.

Full article

Figure 1

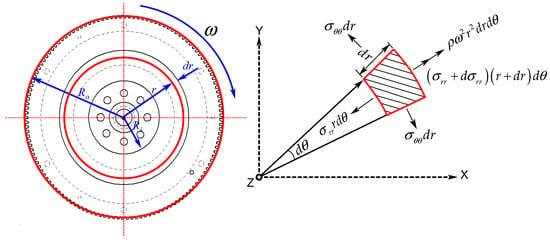

Figure 1

<p>Rotating flywheel and its element.</p> Full article ">Figure 2

<p>Stress distributions: (<b>a</b>) radial variation; (<b>b</b>) tangential variation.</p> Full article ">Figure 3

<p>(<b>a</b>) Variation in tangential vs. radial stresses; (<b>b</b>) displacement along flywheel radius.</p> Full article ">Figure 4

<p>Flowchart of the methodology implied in the FEA simulation.</p> Full article ">Figure 5

<p>First four deformation modes of vibration.</p> Full article ">Figure 6

<p>Waterfall response of mass participation factor.</p> Full article ">Figure 7

<p>Percentage of mass participation factor in the X, Y, and Z directions.</p> Full article ">Figure 8

<p>Four normal vibrational modes in waveform and polar spectrum of flywheel.</p> Full article ">Figure 9

<p>Transverse deflection: (<b>a</b>) time domain; (<b>b</b>) FFT response; (<b>c</b>) CWT spectrum.</p> Full article ">Figure 10

<p>Transverse velocity: (<b>a</b>) time domain; (<b>b</b>) FFT response; (<b>c</b>) CWT spectrum.</p> Full article ">Figure 11

<p>Block diagram of the IF extraction based on HHT.</p> Full article ">Figure 12

<p>Extraction of IMFs and IF based on HHT.</p> Full article ">

<p>Rotating flywheel and its element.</p> Full article ">Figure 2

<p>Stress distributions: (<b>a</b>) radial variation; (<b>b</b>) tangential variation.</p> Full article ">Figure 3

<p>(<b>a</b>) Variation in tangential vs. radial stresses; (<b>b</b>) displacement along flywheel radius.</p> Full article ">Figure 4

<p>Flowchart of the methodology implied in the FEA simulation.</p> Full article ">Figure 5

<p>First four deformation modes of vibration.</p> Full article ">Figure 6

<p>Waterfall response of mass participation factor.</p> Full article ">Figure 7

<p>Percentage of mass participation factor in the X, Y, and Z directions.</p> Full article ">Figure 8

<p>Four normal vibrational modes in waveform and polar spectrum of flywheel.</p> Full article ">Figure 9

<p>Transverse deflection: (<b>a</b>) time domain; (<b>b</b>) FFT response; (<b>c</b>) CWT spectrum.</p> Full article ">Figure 10

<p>Transverse velocity: (<b>a</b>) time domain; (<b>b</b>) FFT response; (<b>c</b>) CWT spectrum.</p> Full article ">Figure 11

<p>Block diagram of the IF extraction based on HHT.</p> Full article ">Figure 12

<p>Extraction of IMFs and IF based on HHT.</p> Full article ">

Open AccessArticle

Theoretical and Experimental Vibration Generation in a Coaxial Pulse-Tube Cryocooler

by

Hongyan Wei, Yulan Li, Yuqiang Xun and Huaqiang Zhong

Vibration 2024, 7(4), 1226-1247; https://doi.org/10.3390/vibration7040063 - 11 Dec 2024

Abstract

►▼

Show Figures

The microphonic noise induced by the vibration from cryocoolers has been found to cause energy resolution degradation in vibration-sensitive instruments. In this paper, theoretical and experimental research on the vibration generation mechanism of an aerospace-grade coaxial pulse-tube cryocooler (CPTC) is presented. Accordingly, suggestions

[...] Read more.

The microphonic noise induced by the vibration from cryocoolers has been found to cause energy resolution degradation in vibration-sensitive instruments. In this paper, theoretical and experimental research on the vibration generation mechanism of an aerospace-grade coaxial pulse-tube cryocooler (CPTC) is presented. Accordingly, suggestions for suppressing the vibration of the pulse-tube cryocooler are provided. A vibration model for the Oxford-type dual-opposed linear compressor is established, and the mechanism of vibration induced by the compressor is theoretically analyzed. A numerical simulation indicates that deviations in the compressor’s inductance coefficient, electromagnetic force coefficient, and flexure spring stiffness coefficient significantly affect the axial vibration of the compressor. The theoretical and experimental studies show that the high-order harmonic vibrations of the compressor are determined by both the resonance of the flexure springs and the high-order harmonics of the driving power supply. Through experiments and simulations, it is revealed that the dynamic gas pressure only induces vibration axially at the cold tip, while the radial vibration at the cold tip is determined by the heat head ‘s vibration and the structural response characteristics of the cold finger.

Full article

Figure 1

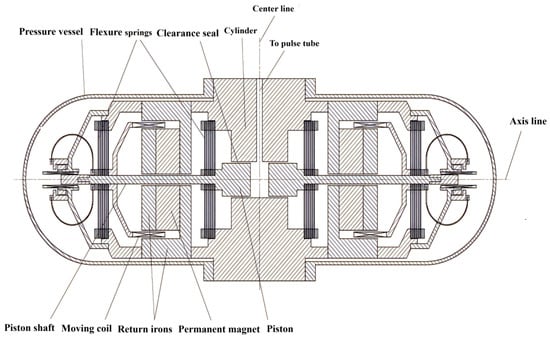

Figure 1

<p>Schematic of the Oxford-style dual-opposed moving-coil linear compressor.</p> Full article ">Figure 2

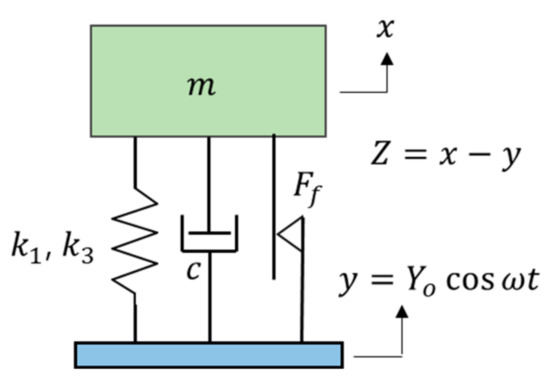

<p>Schematic of a single-degree-of-freedom mechanical force system in a compressor.</p> Full article ">Figure 3

<p>Equivalent circuit diagram in a compressor.</p> Full article ">Figure 4

<p>Diagram of the Simulink model for the dual-opposed compressor’s vibration analysis.</p> Full article ">Figure 5

<p>Schematic diagram of the cold finger vibration model.</p> Full article ">Figure 6

<p>Schematic diagram of gas micro cluster flow inside the cold finger.</p> Full article ">Figure 7

<p>Stress distribution diagrams of the cold finger on the transverse and longitudinal sections under radial pressure (<b>a</b>) and axial pressure (<b>b</b>).</p> Full article ">Figure 8

<p>Schematic diagram of axial strain displacement under the action of axial pressure waves (<b>a</b>) and radial pressure (<b>b</b>) at the cold tip.</p> Full article ">Figure 9

<p>Strain displacement generated by pressure waves at the cold tip.</p> Full article ">Figure 10

<p>Variation in cold tip axial vibration acceleration with pressure amplitude.</p> Full article ">Figure 11

<p>Test system of the drive power supply’s harmonic distortion.</p> Full article ">Figure 12

<p>NF (<b>a</b>) and ITM 7383 (<b>b</b>) power voltage quality.</p> Full article ">Figure 13

<p>Test system of compressor drive power distortion vs. vibration force.</p> Full article ">Figure 14

<p>Characterization of compressor operating current (<b>a</b>) and compressor vibration force (<b>b</b>) under different drive powers.</p> Full article ">Figure 15

<p>Compressor vibration force under different drive powers.</p> Full article ">Figure 16

<p>Illustration of the flexure spring configuration.</p> Full article ">Figure 17

<p>The test platform of flexure springs’ resonance impact (<b>a</b>) and laser displacement monitoring points (<b>b</b>).</p> Full article ">Figure 18

<p>Flexure springs’ axial displacement with varying frequency.</p> Full article ">Figure 19

<p>Flexure springs’ axial displacement on the left (<b>a</b>) and right (<b>b</b>) with varying frequency.</p> Full article ">Figure 20

<p>Axial vibration force spectrum of compressor during flexure spring resonance.</p> Full article ">Figure 21

<p>Flexure spring driving displacement at 108.8 Hz (resonance) (<b>a</b>) and compressor’s vibration force FFT spectrum (<b>b</b>).</p> Full article ">Figure 22

<p>Flexure spring driving displacement at 77.2 Hz (resonance) (<b>a</b>) and compressor vibration force FFT spectrum (<b>b</b>).</p> Full article ">Figure 23

<p>Flexure spring driving displacement at 136.8 Hz (resonance) (<b>a</b>) and compressor’s vibration force FFT spectrum (<b>b</b>).</p> Full article ">Figure 24

<p>System for testing the cold finger’s vibration acceleration.</p> Full article ">Figure 25

<p>FFT spectral distribution of vibration acceleration in cold finger radial (<b>a</b>), vertical (<b>b</b>) and axial (<b>c</b>) directions under a charge pressure 0 MPa.</p> Full article ">Figure 26

<p>Cold tip’s radial vibration acceleration gains factor (<b>a</b>) and FFT spectra of radial vibration acceleration at heat head 2 (<b>b</b>) and cold tip (<b>c</b>) under different charge pressures.</p> Full article ">Figure 27

<p>Cold tip’s axial vibration acceleration gain factor: (<b>a</b>) FFT spectra of axial vibration acceleration at heat head 2 (<b>b</b>) and cold tip (<b>c</b>) under different charge pressures.</p> Full article ">Figure 28

<p>Cold tip’s vertical vibration acceleration gains factor (<b>a</b>) and FFT spectra of vertical vibration acceleration at heat head 2 (<b>b</b>) and cold tip (<b>c</b>) under different charge pressures.</p> Full article ">Figure 29

<p>Axial vibration acceleration at the cold tip under different driving powers.</p> Full article ">

<p>Schematic of the Oxford-style dual-opposed moving-coil linear compressor.</p> Full article ">Figure 2

<p>Schematic of a single-degree-of-freedom mechanical force system in a compressor.</p> Full article ">Figure 3

<p>Equivalent circuit diagram in a compressor.</p> Full article ">Figure 4

<p>Diagram of the Simulink model for the dual-opposed compressor’s vibration analysis.</p> Full article ">Figure 5

<p>Schematic diagram of the cold finger vibration model.</p> Full article ">Figure 6

<p>Schematic diagram of gas micro cluster flow inside the cold finger.</p> Full article ">Figure 7

<p>Stress distribution diagrams of the cold finger on the transverse and longitudinal sections under radial pressure (<b>a</b>) and axial pressure (<b>b</b>).</p> Full article ">Figure 8