-

Evaluation of Differences in Solubilities in Organic Solvents of Wood-Based Industrial Kraft Lignins Using Hansen Parameters

-

Simple Green Purification of Spilanthol Derived from Natural Deep Eutectic Solvent and Ethanolic Acmella oleracea Extract

-

Volatile Compounds of Italian Honeys Assessed via HS-SPME-GC-MS for Authentication Using the Genetic Algorithm

Journal Description

Separations

Separations

- formerly Chromatography - is an international, peer-reviewed, open access journal on separation and purification science and technology in all areas of chemical, biological, physical science, and separation performance published monthly online by MDPI. The Central European Group of Separation Sciences (CEGSS) is affiliated with Separations and their members receive discounts on the article processing charges.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- High Visibility: indexed within Scopus, SCIE (Web of Science), CAPlus / SciFinder, and other databases.

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 15.1 days after submission; acceptance to publication is undertaken in 2.9 days (median values for papers published in this journal in the second half of 2024).

- Recognition of Reviewers: reviewers who provide timely, thorough peer-review reports receive vouchers entitling them to a discount on the APC of their next publication in any MDPI journal, in appreciation of the work done.

- Companion journal: Purification.

Impact Factor:

2.5 (2023);

5-Year Impact Factor:

2.6 (2023)

Latest Articles

Bioactive Properties of Pentacalia vaccinioides (Kunth) Cuatrec. (Asteraceae) Essential Oils: Evaluation of Antimicrobial and Antioxidant Activities

Separations 2025, 12(1), 9; https://doi.org/10.3390/separations12010009 - 5 Jan 2025

Abstract

Essential oils (EOs) have unique properties, such as antibacterial, antioxidant, and antiviral activities, which are beneficial in various industries, including cosmetics, food, and pharmaceuticals. In this study, the antioxidant and antimicrobial activities of Pentacalia vaccinioides EOs obtained from leaves and flowers (fresh and

[...] Read more.

Essential oils (EOs) have unique properties, such as antibacterial, antioxidant, and antiviral activities, which are beneficial in various industries, including cosmetics, food, and pharmaceuticals. In this study, the antioxidant and antimicrobial activities of Pentacalia vaccinioides EOs obtained from leaves and flowers (fresh and dried plant material) were evaluated using hydrodistillation (HD), steam distillation (SD), simultaneous distillation–extraction (SDE), and solid-phase microextraction (SPME) techniques. Antimicrobial activity (minimum inhibitory concentration, MIC) and antioxidant capacity (half-maximal inhibitory concentration, IC50) were determined. The identification and quantification of the compounds present in the EOs were conducted by gas chromatography coupled to mass spectrometry (GC-MS). The main secondary metabolites identified in most samples obtained by different extraction techniques included phenol (~18%), 1S-α-pinene (~15%), β-phellandrene (~13%), β-pinene (~12%), 4-terpineol (~10%), γ-terpinene (~10%), trans-nerolidol (~8%), limonene (~8%), and β-thujene (~6%). EOs obtained by HD, SD, and SDE exhibited antioxidant activity, with IC50 values between 621.7 and 696.6 µg/mL. Additionally, the EOs demonstrated bactericidal activity against Bacillus subtilis and Staphylococcus aureus, with MIC values of 5.0 and 45 µg/mL, respectively. Escherichia coli and Pseudomonas aeruginosa did not show antimicrobial susceptibility to EOs. This study constitutes the first evaluation of Pentacalia vaccinioides EOs, demonstrating their bioactive potential and the relevance of the extraction method. The findings highlight this species as a promising source of natural compounds for therapeutic and preservative applications, depending on the type of plant material and extraction technique used. Future research should investigate how microclimatic conditions and plant development affect the chemical composition and elucidate the molecular mechanisms behind the observed bioactivities to better understand their cellular actions. Furthermore, the evaluation of the applications of EOs and hydrolates in the pharmaceutical and food industries, along with the exploration of the bioactive potential of extraction-derived hydrolates, offers a promising avenue to maximize plant utility.

Full article

(This article belongs to the Special Issue Essential Oils: Extraction, Chemical Composition, and Bioactivities)

Open AccessArticle

Phytochemical Profile Screening and Selected Bioactivity of Myrtus communis Berries Extracts Obtained from Ultrasound-Assisted and Supercritical Fluid Extraction

by

Ilir Mërtiri, Gigi Coman, Mihaela Cotârlet, Mihaela Turturică, Nicoleta Balan, Gabriela Râpeanu, Nicoleta Stănciuc and Liliana Mihalcea

Separations 2025, 12(1), 8; https://doi.org/10.3390/separations12010008 - 3 Jan 2025

Abstract

This research paper investigates the phytochemical profile, antioxidant activity, antidiabetic potential, and antibacterial activity of Myrtus communis berries. Two extraction methods were employed to obtain the extracts: solid–liquid ultrasound-assisted extraction (UAE) and supercritical fluid extraction (SFE). The extracts were characterized using spectrophotometric methods

[...] Read more.

This research paper investigates the phytochemical profile, antioxidant activity, antidiabetic potential, and antibacterial activity of Myrtus communis berries. Two extraction methods were employed to obtain the extracts: solid–liquid ultrasound-assisted extraction (UAE) and supercritical fluid extraction (SFE). The extracts were characterized using spectrophotometric methods and Reversed-Phase High-Performance Liquid Chromatography (RP-HPLC). The UAE extract exhibited higher total flavonoid and anthocyanin content, while the SFE extract prevailed in total phenolic content and antioxidant activity in the DPPH radical screening assay. RP-HPLC characterization identified and quantified several polyphenolic compounds. In the UAE extract, epigallocatechin was found in a concentration of 2656.24 ± 28.15 µg/g dry weight (DW). In the SFE extract, cafestol was the identified compound with the highest content at a level of 29.65 ± 0.03 µg/g DW. Both extracts contained several anthocyanin compounds, including cyanidin 3-O-glucoside chloride, cyanidin-3-O-rutinoside chloride, malvidin-3-O-glucoside chloride, pelargonidin 3-O-glucoside chloride, peonidin 3-O-glucoside chloride, and peonidin-3-O-rutinoside chloride. The antidiabetic potential was evaluated in vitro by measuring the inhibition of α-amylase from porcine pancreas (type I-A). The results highlighted the ability of myrtle berry extracts to inhibit α-amylase enzymatic activity, suggesting its potential as an alternative for controlling postprandial hyperglycemia. The UAE extract showed the lowest IC50 value among the two extracts, with an average of 8.37 ± 0.52 µg/mL DW. The antibacterial activity of the extracts was assessed in vitro against Bacillus spp., Escherichia coli, and Staphylococcus aureus using the disk diffusion method. Both myrtle berry extracts exhibited similar antibacterial activity against the tested bacterial strains. The results support further investigation of myrtle berries extracts as a potential ingredient in functional food formulation, particularly due to its antioxidant, antidiabetic, and antibacterial properties.

Full article

(This article belongs to the Special Issue Green Extraction Techniques of Bioactive Compounds from Natural Sources)

►▼

Show Figures

Figure 1

Figure 1

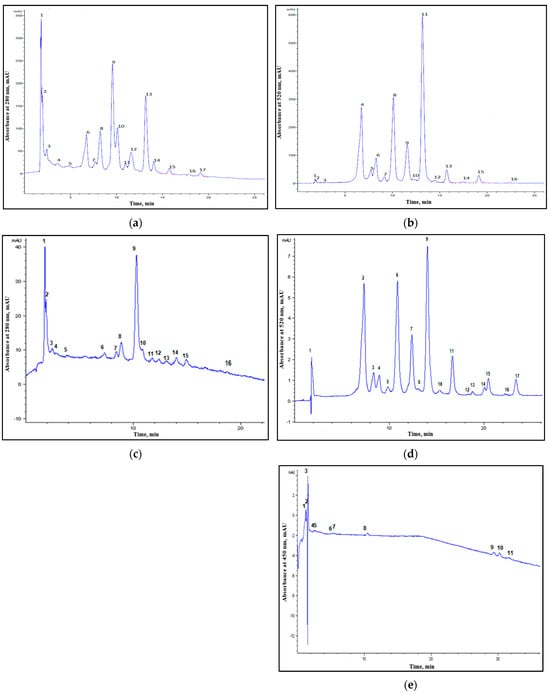

<p>Chromatograms of wild myrtle berries extracts. UAE extract: (<b>a</b>) 280 nm; 2—gallic acid; 5—epicatechin; 8—ferulic acid; 10—synapic acid; 1, 3, 4, 6, 7, 9, 11–17—unidentified compounds. (<b>b</b>) 520 nm; 2—gallic acid; 7—kuromanin chloride; 8—synapic acid; 10—naringin; 11—rutin trihydrate; 12—peonidin-3-<span class="html-italic">O</span>-rutinoside chloride; 15—quercetin; 1, 3–6, 9, 13, 14, 16—unidentified compounds. SFE extract: (<b>c</b>) 280 nm; 1—cafestol; 2—gallic acid; 7—ferulic acid; 16—quercetin; 3–6, 8–15—unidentified compounds. (<b>d</b>) 520 nm; 4—kuromanin chloride; 5—callistephin chloride; 9—oenin chloride; 1–3, 6–8, 10–17—unidentified compounds. (<b>e</b>) 450 nm: 8—zeaxanthin; 1–7, 9–11—unidentified compounds.</p> Full article ">Figure 2

<p>Antibacterial results of disk diffusion method against the tested bacterial strains. The samples codes represent the following: UAE—myrtle berries extract from ultrasound-assisted extraction; SFE—myrtle berries extract extract from supercritical fluid extraction; CC1—ciprofloxacin (positive control); CS—solubilization solvent (negative control).</p> Full article ">

<p>Chromatograms of wild myrtle berries extracts. UAE extract: (<b>a</b>) 280 nm; 2—gallic acid; 5—epicatechin; 8—ferulic acid; 10—synapic acid; 1, 3, 4, 6, 7, 9, 11–17—unidentified compounds. (<b>b</b>) 520 nm; 2—gallic acid; 7—kuromanin chloride; 8—synapic acid; 10—naringin; 11—rutin trihydrate; 12—peonidin-3-<span class="html-italic">O</span>-rutinoside chloride; 15—quercetin; 1, 3–6, 9, 13, 14, 16—unidentified compounds. SFE extract: (<b>c</b>) 280 nm; 1—cafestol; 2—gallic acid; 7—ferulic acid; 16—quercetin; 3–6, 8–15—unidentified compounds. (<b>d</b>) 520 nm; 4—kuromanin chloride; 5—callistephin chloride; 9—oenin chloride; 1–3, 6–8, 10–17—unidentified compounds. (<b>e</b>) 450 nm: 8—zeaxanthin; 1–7, 9–11—unidentified compounds.</p> Full article ">Figure 2

<p>Antibacterial results of disk diffusion method against the tested bacterial strains. The samples codes represent the following: UAE—myrtle berries extract from ultrasound-assisted extraction; SFE—myrtle berries extract extract from supercritical fluid extraction; CC1—ciprofloxacin (positive control); CS—solubilization solvent (negative control).</p> Full article ">

Open AccessArticle

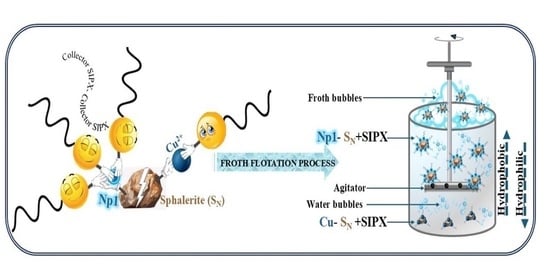

Research on the Flotation Mechanism of Microemulsion Collector Enhanced Removal of Dyeing Impurities from Phosphogypsum

by

Xiaosheng Yu, Lijun Deng, Changpan Shen, Huiyong Li, Jingchao Li, Yijun Cao, Guoli Zhou and Guosheng Li

Separations 2025, 12(1), 7; https://doi.org/10.3390/separations12010007 - 31 Dec 2024

Abstract

Phosphogypsum is an industrial byproduct that is limited in its high-value application due to the presence of dyeing impurities (such as organic matter and carbon black). The flotation method has been verified to be effective in separating these dyeing impurities from gypsum. In

[...] Read more.

Phosphogypsum is an industrial byproduct that is limited in its high-value application due to the presence of dyeing impurities (such as organic matter and carbon black). The flotation method has been verified to be effective in separating these dyeing impurities from gypsum. In this study, microemulsion was used as the collector method of dyeing impurities for their separation from gypsum. The results of flotation tests showed that the microemulsion collector exhibited excellent collection capability and selectivity under natural pH conditions (pH = 1.5). With a microemulsion collector consumption of 400 g/t, purified gypsum of 65.1% whiteness, 95.74% yield, and 97.01% recovery was obtained. The purified gypsum of 65.1% whiteness, 95.74% yield, 97.01 recovery obtained by a used microemulsion collector amount of 400 g/t was better than using the same dosage of kerosene collector. The dispersion behavior of the microemulsion collector was studied by low-temperature transmission electron microscopy. The microemulsion collector demonstrated superior dispersibility, as it forms nano-oil droplets with an average size of 176.83 nm in the pulp, resolving issues associated with poor dispersibility observed in traditional kerosene collectors. Additionally, the nano-oil droplets effectively adsorbed onto the surface of dyeing impurities through hydrogen bonding, enhancing their hydrophobicity. Therefore, the microemulsion collector holds great potential for application in flotation whitening processes involving phosphogypsum.

Full article

(This article belongs to the Special Issue Separation and Extraction Technology in Mineral Processing)

►▼

Show Figures

Figure 1

Figure 1

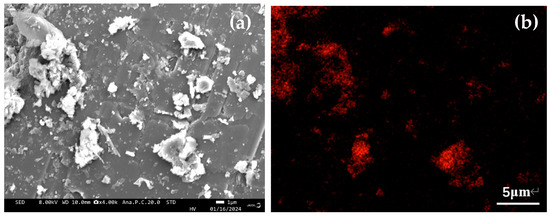

<p>SEM images of PG sample ((<b>a</b>) the microstructure of and (<b>b</b>) the elements mapping scanning of the PG raw ore.)</p> Full article ">Figure 2

<p>XRD pattern of the PG sample.</p> Full article ">Figure 3

<p>Flow chart of microemulsion preparation (<b>a</b>) and the reverse flotation tests (<b>b</b>).</p> Full article ">Figure 3 Cont.

<p>Flow chart of microemulsion preparation (<b>a</b>) and the reverse flotation tests (<b>b</b>).</p> Full article ">Figure 4

<p>TG-DTG pattern of the dyeing impurities.</p> Full article ">Figure 5

<p>Size distribution of oil droplets generated by the dispersion of the microemulsion (<b>a</b>) and kerosene (<b>b</b>).</p> Full article ">Figure 6

<p>Morphology of the microemulsion (<b>a</b>) and nano-oil droplets (<b>b</b>).</p> Full article ">Figure 7

<p>Flotation results at different dosages of kerosene (<b>a</b>) and microemulsion (<b>b</b>) collectors.</p> Full article ">Figure 8

<p>SEM images of raw PG (<b>a</b>) and gypsum concentrate (<b>b</b>).</p> Full article ">Figure 9

<p>Contact angles of gypsum (<b>a</b>) and dyeing impurities (<b>b</b>) before and after being treated with kerosene and microemulsion.</p> Full article ">Figure 10

<p>FT-IR results of gypsum and dyeing impurities treated by different collectors.</p> Full article ">Figure 11

<p>XPS results of dyeing impurities treated by different collectors.</p> Full article ">Figure 12

<p>Schematic diagram of the microemulsion collector enhancing flotation performance of PG.</p> Full article ">

<p>SEM images of PG sample ((<b>a</b>) the microstructure of and (<b>b</b>) the elements mapping scanning of the PG raw ore.)</p> Full article ">Figure 2

<p>XRD pattern of the PG sample.</p> Full article ">Figure 3

<p>Flow chart of microemulsion preparation (<b>a</b>) and the reverse flotation tests (<b>b</b>).</p> Full article ">Figure 3 Cont.

<p>Flow chart of microemulsion preparation (<b>a</b>) and the reverse flotation tests (<b>b</b>).</p> Full article ">Figure 4

<p>TG-DTG pattern of the dyeing impurities.</p> Full article ">Figure 5

<p>Size distribution of oil droplets generated by the dispersion of the microemulsion (<b>a</b>) and kerosene (<b>b</b>).</p> Full article ">Figure 6

<p>Morphology of the microemulsion (<b>a</b>) and nano-oil droplets (<b>b</b>).</p> Full article ">Figure 7

<p>Flotation results at different dosages of kerosene (<b>a</b>) and microemulsion (<b>b</b>) collectors.</p> Full article ">Figure 8

<p>SEM images of raw PG (<b>a</b>) and gypsum concentrate (<b>b</b>).</p> Full article ">Figure 9

<p>Contact angles of gypsum (<b>a</b>) and dyeing impurities (<b>b</b>) before and after being treated with kerosene and microemulsion.</p> Full article ">Figure 10

<p>FT-IR results of gypsum and dyeing impurities treated by different collectors.</p> Full article ">Figure 11

<p>XPS results of dyeing impurities treated by different collectors.</p> Full article ">Figure 12

<p>Schematic diagram of the microemulsion collector enhancing flotation performance of PG.</p> Full article ">

Open AccessArticle

Kinetics of Supercritical CO2 Extraction from Burrito (Aloysia polystachya) Leaves and Sucupira-Preta (Bowdichia virgilioides) Seeds

by

Gabrielle Vaz Vieira, Michel Rubens dos Reis Souza, Carlos Toshiyuki Hiranobe, José Eduardo Goncalves, Cristiane Mengue Feniman Moritz, Otávio Akira Sakai, Leila Maria Sotocorno e Silva, Michael Jones da Silva, Erivaldo Antônio da Silva, Renivaldo José dos Santos, Edson Antônio da Silva, Lucio Cardozo-Filho and Leandro Ferreira-Pinto

Separations 2025, 12(1), 6; https://doi.org/10.3390/separations12010006 - 31 Dec 2024

Abstract

►▼

Show Figures

This study investigated the application of supercritical carbon dioxide (CO2) for the extraction of essential oils from plant materials with anxiolytic potential, focusing on the leaves of burrito (Aloysia polystachya) and the seeds of sucupira-preta (Bowdichia virgilioides).

[...] Read more.

This study investigated the application of supercritical carbon dioxide (CO2) for the extraction of essential oils from plant materials with anxiolytic potential, focusing on the leaves of burrito (Aloysia polystachya) and the seeds of sucupira-preta (Bowdichia virgilioides). The supercritical extraction technique was chosen for its ability to produce high-purity extracts without residual solvents and to reduce the environmental impact. This study evaluated the influence of temperature (40 °C, 50 °C, and 60 °C) and pressure (22 MPa, 25 MPa, and 28 MPa) on extraction efficiency using a 22 factorial design with triplicates at the central point. The maximum yields were 1.2% for burrito leaves and 4.2% for sucupira-preta seeds. Despite their relatively low yields, the extracts contained a diverse range of chemical compounds, including fatty acids (oleic, linoleic, and palmitic acids), squalene, β-carotene, vitamin E, and other bioactive molecules with antioxidant, anti-inflammatory, and immunomodulatory properties. Statistical analysis demonstrated that pressure was the most influential factor affecting yield, whereas temperature played a secondary role. The Sovová kinetic model provided a good fit for the extraction curves, with determination coefficients (R2) above 0.95, thus validating the efficiency of the method. These results highlight the pharmaceutical potential of these extracts, particularly for therapeutic and anxiolytic purposes.

Full article

Figure 1

Figure 1

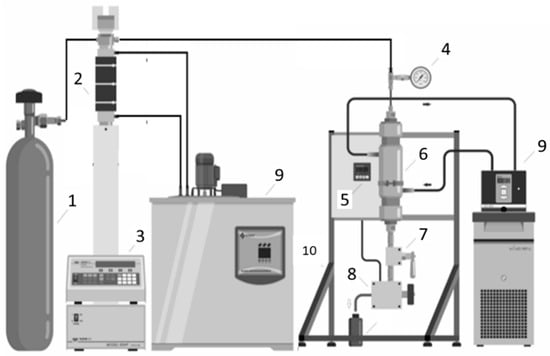

<p>A schematic of the experimental supercritical extraction unit: 1—CO<sub>2</sub> cylinder; 2—syringe pump; 3—thermostatic bath; 4—pressure indicator; 5—temperature controller/indicator; 6—extractor; 7—valve; 8—needle-type valve attached to an aluminum jacket for heating; 9—thermostatic bath; 10—aluminum structure.</p> Full article ">Figure 2

<p>Experimental kinetic extraction curves with supercritical CO<sub>2</sub> fitted using the Sovová model (<span class="html-fig-inline" id="separations-12-00006-i001"><img alt="Separations 12 00006 i001" src="/separations/separations-12-00006/article_deploy/html/images/separations-12-00006-i001.png"/></span>) of burrito leaves: 40 °C (■, 22 MPa; ▲, 28 MPa); 50 °C (<span class="html-fig-inline" id="separations-12-00006-i002"><img alt="Separations 12 00006 i002" src="/separations/separations-12-00006/article_deploy/html/images/separations-12-00006-i002.png"/></span>, 25 MPa); 60 °C (●, 22 MPa; ▼, 28 MPa) with a constant flow rate of 2.0 mL min<sup>−1</sup>.</p> Full article ">Figure 3

<p>Experimental kinetic extraction curves with supercritical CO<sub>2</sub> fitted using Sovová model (<span class="html-fig-inline" id="separations-12-00006-i001"><img alt="Separations 12 00006 i001" src="/separations/separations-12-00006/article_deploy/html/images/separations-12-00006-i001.png"/></span>) of sucupira-preta seeds: 40 °C (■, 22 MPa; ▲, 28 MPa); 50 °C (<span class="html-fig-inline" id="separations-12-00006-i002"><img alt="Separations 12 00006 i002" src="/separations/separations-12-00006/article_deploy/html/images/separations-12-00006-i002.png"/></span>, 25 MPa); 60 °C (●, 22 MPa; ▼, 28 MPa) with a constant flow rate of 2.0 mL min<sup>−1</sup>.</p> Full article ">Figure 4

<p>A response surface plot illustrating the extraction yield of oil from burrito leaves as a function of temperature and pressure, with a constant flow rate of 2.0 mL min<sup>−1</sup>.</p> Full article ">Figure 5

<p>A response surface plot showing the oil extraction yield from sucupira-preta seeds as influenced by temperature and pressure at a fixed flow rate of 2.0 mL min<sup>−1</sup>.</p> Full article ">Figure 6

<p>Pareto chart: analysis of linear effects of variables. (<b>A</b>) Burrito leaves and (<b>B</b>) sucupira-preta seeds.</p> Full article ">

<p>A schematic of the experimental supercritical extraction unit: 1—CO<sub>2</sub> cylinder; 2—syringe pump; 3—thermostatic bath; 4—pressure indicator; 5—temperature controller/indicator; 6—extractor; 7—valve; 8—needle-type valve attached to an aluminum jacket for heating; 9—thermostatic bath; 10—aluminum structure.</p> Full article ">Figure 2

<p>Experimental kinetic extraction curves with supercritical CO<sub>2</sub> fitted using the Sovová model (<span class="html-fig-inline" id="separations-12-00006-i001"><img alt="Separations 12 00006 i001" src="/separations/separations-12-00006/article_deploy/html/images/separations-12-00006-i001.png"/></span>) of burrito leaves: 40 °C (■, 22 MPa; ▲, 28 MPa); 50 °C (<span class="html-fig-inline" id="separations-12-00006-i002"><img alt="Separations 12 00006 i002" src="/separations/separations-12-00006/article_deploy/html/images/separations-12-00006-i002.png"/></span>, 25 MPa); 60 °C (●, 22 MPa; ▼, 28 MPa) with a constant flow rate of 2.0 mL min<sup>−1</sup>.</p> Full article ">Figure 3

<p>Experimental kinetic extraction curves with supercritical CO<sub>2</sub> fitted using Sovová model (<span class="html-fig-inline" id="separations-12-00006-i001"><img alt="Separations 12 00006 i001" src="/separations/separations-12-00006/article_deploy/html/images/separations-12-00006-i001.png"/></span>) of sucupira-preta seeds: 40 °C (■, 22 MPa; ▲, 28 MPa); 50 °C (<span class="html-fig-inline" id="separations-12-00006-i002"><img alt="Separations 12 00006 i002" src="/separations/separations-12-00006/article_deploy/html/images/separations-12-00006-i002.png"/></span>, 25 MPa); 60 °C (●, 22 MPa; ▼, 28 MPa) with a constant flow rate of 2.0 mL min<sup>−1</sup>.</p> Full article ">Figure 4

<p>A response surface plot illustrating the extraction yield of oil from burrito leaves as a function of temperature and pressure, with a constant flow rate of 2.0 mL min<sup>−1</sup>.</p> Full article ">Figure 5

<p>A response surface plot showing the oil extraction yield from sucupira-preta seeds as influenced by temperature and pressure at a fixed flow rate of 2.0 mL min<sup>−1</sup>.</p> Full article ">Figure 6

<p>Pareto chart: analysis of linear effects of variables. (<b>A</b>) Burrito leaves and (<b>B</b>) sucupira-preta seeds.</p> Full article ">

Open AccessArticle

A Compact Instrument for Temperature-Programming-Assisted Capillary–Nanoliquid Chromatography

by

Lincon Coutinho Marins, Alessandra Maffei Monteiro, Vivane Lopes Leal, Deyber Arley Vargas Medina, Edwin Martin Cardenas and Fernando Mauro Lanças

Separations 2025, 12(1), 5; https://doi.org/10.3390/separations12010005 - 30 Dec 2024

Abstract

The miniaturization of liquid chromatography (LC) columns to capillary and nanoscales allows temperature programming to be an effective alternative to solvent gradients for modulating eluotropic strength. This approach simplifies instrument design and operation, as a single pump can suffice to achieve efficient separations.

[...] Read more.

The miniaturization of liquid chromatography (LC) columns to capillary and nanoscales allows temperature programming to be an effective alternative to solvent gradients for modulating eluotropic strength. This approach simplifies instrument design and operation, as a single pump can suffice to achieve efficient separations. This study presents the development and application of a compact, lab-built high-pressure system for temperature-programmed capillary and nanoLC separations. The instrument includes a high-pressure capillary–nanoflow syringe pump, a time-based nanoliter injection system, a programmable capillary column oven for controlled temperature gradients, and a UV-Vis detection system with a custom nanoliter-scale detection cell. Each system component was designed and built in-house, with rigorous calibration to ensure accuracy and operational reliability. Experimental data confirm the system’s capability to deliver precise, reproducible temperature, and flow rates. Functionality was validated through temperature-programmed separations on packed and open tubular capillary columns. The results demonstrated that the developed instrument offers enhanced separation efficiency and reduced analysis time compared to isothermal methods, underscoring its potential for advanced applications in miniaturized liquid chromatography.

Full article

(This article belongs to the Special Issue Separation Techniques on a Miniaturized Scale)

►▼

Show Figures

Figure 1

Figure 1

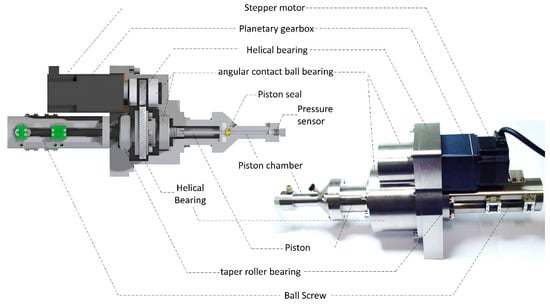

<p>Illustration of the mechanical architecture of the developed capillary–nanoflow high-pressure syringe pump, highlighting its main actuation components.</p> Full article ">Figure 2

<p>Photographs of the developed capillary–NanoLC temperature-programmable oven: (<b>a</b>) metal body of the oven; (<b>b</b>) Fiberfrax<sup>®</sup> thermal insulation fabric; (<b>c</b>) ceramic tube wrapped with resistive nickel–chromium heating wire; (<b>d</b>) cooling fan; (<b>e</b>) Celeron cooling duct; (<b>f</b>) servomotor controlling the cooling windows; (<b>g</b>) cooling windows; (<b>h</b>) fully assembled oven.</p> Full article ">Figure 3

<p>The assembly process of the capillary–NanoLC detection cell: (<b>a</b>) anodized aluminum blocks used for supporting the optical path length; (<b>b</b>) bending process of the capillary tube to form the optical path; (<b>c</b>) optical path length featuring 7.9 mm; (<b>d</b>) fully assembled detection cell, including the central metallic tube supporting the optical path length.</p> Full article ">Figure 4

<p>Measure vs. set flow rate: (<b>a</b>) in the 0–250 µL/min range; (<b>b</b>) in the 0–10 µL/min range; (<b>c</b>) in the 0–1.0 µL/min range.</p> Full article ">Figure 5

<p>Calibration of the injection volume: (<b>A</b>) a representative chromatogram of the mixture is used for calibration. The analysis used a fused silica capillary column (250 μm i.d., 15 cm length) packed with 3.0 μm C18 Pinnacle II (Restek) stationary phase. The mobile phase consisted of acetonitrile/water (48:62) acidified with 0.5% glacial acetic acid, delivered at a flow rate of 3 μL/min. Peak areas were calculated from chromatograms recorded at 240 nm; (<b>B</b>) relationship between the injection time and the injected volume, showing linearity in the 0–300 ms range and an exponential decrease in volume per unit time beyond this point; (<b>C</b>) correlation between the adjusted injection volume and the experimentally measured volume after calibration, demonstrating the accuracy of the system post-calibration.</p> Full article ">Figure 6

<p>Performance assessment of the developed temperature-programmable oven: (<b>a</b>) example of temperature control during an isothermal run at 60 °C; (<b>b</b>) correspondence between the temperature set by the user and the experimentally measured temperature; (<b>c</b>) relationship between the heating power required and the temperature ramp slope (°C/min); (<b>d</b>) an example of the oven’s operation during a run includes both isothermal and temperature gradient segments.</p> Full article ">Figure 7

<p>Chromatograms obtained using both the commercial microcell (Shimadzu) and the capillary cell developed in this work. The analysis was performed using a lab-made C-18 250 µm i.d ×150 mm packed column and a flow rate of 3.0 μL/min, with an injection volume of 60 nL. The elution order of the analytes was as follows: (1) naphthalene, (2) phenanthrene, and (3) anthracene. The concentration of each analyte was 30 mg/L.</p> Full article ">Figure 8

<p>Graphs showing variation as a function of the squared retention volume for the (<b>a</b>) lab-made and (<b>b</b>) commercial instruments.</p> Full article ">Figure 9

<p>Separation of PAHs (50 mg/mL) on a packed C18 capillary column (14 cm length, 250 µm i.d., 3.5 µm particle size) at a flow rate of 5.0 µL/min, using acetonitrile (70:30) as the mobile phase, under two conditions: (<b>a</b>) isothermal mode (no temperature programming) and (<b>b</b>) with temperature programming. Analytes: naphthalene (1), acenaphthylene (2), acenaphthene (3), fluorene (4), phenanthrene (5), anthracene (6), chrysene (7), and dibenzo(a,h)anthracene (8).</p> Full article ">Figure 10

<p>Separating alkylbenzene compounds using a WCOT column (5 m length, 50 μm i.d.): (<b>a</b>) without temperature programming and (<b>b</b>) with temperature programming. Peaks: uracil (1), Toluene (2), ethylbenzene (3), butylbenzene (4), pentylbenzene (5), and heptylbenzene (6).</p> Full article ">Figure 11

<p>Separating alkylbenzene compounds using a PLOT column (5 m length, 50 μm i.d.): (<b>a</b>) without temperature programming and (<b>b</b>) with temperature programming. Peaks: uracil (1), toluene (2), ethylbenzene (3), butylbenzene (4), pentylbenzene (5), and heptylbenzene (6).</p> Full article ">

<p>Illustration of the mechanical architecture of the developed capillary–nanoflow high-pressure syringe pump, highlighting its main actuation components.</p> Full article ">Figure 2

<p>Photographs of the developed capillary–NanoLC temperature-programmable oven: (<b>a</b>) metal body of the oven; (<b>b</b>) Fiberfrax<sup>®</sup> thermal insulation fabric; (<b>c</b>) ceramic tube wrapped with resistive nickel–chromium heating wire; (<b>d</b>) cooling fan; (<b>e</b>) Celeron cooling duct; (<b>f</b>) servomotor controlling the cooling windows; (<b>g</b>) cooling windows; (<b>h</b>) fully assembled oven.</p> Full article ">Figure 3

<p>The assembly process of the capillary–NanoLC detection cell: (<b>a</b>) anodized aluminum blocks used for supporting the optical path length; (<b>b</b>) bending process of the capillary tube to form the optical path; (<b>c</b>) optical path length featuring 7.9 mm; (<b>d</b>) fully assembled detection cell, including the central metallic tube supporting the optical path length.</p> Full article ">Figure 4

<p>Measure vs. set flow rate: (<b>a</b>) in the 0–250 µL/min range; (<b>b</b>) in the 0–10 µL/min range; (<b>c</b>) in the 0–1.0 µL/min range.</p> Full article ">Figure 5

<p>Calibration of the injection volume: (<b>A</b>) a representative chromatogram of the mixture is used for calibration. The analysis used a fused silica capillary column (250 μm i.d., 15 cm length) packed with 3.0 μm C18 Pinnacle II (Restek) stationary phase. The mobile phase consisted of acetonitrile/water (48:62) acidified with 0.5% glacial acetic acid, delivered at a flow rate of 3 μL/min. Peak areas were calculated from chromatograms recorded at 240 nm; (<b>B</b>) relationship between the injection time and the injected volume, showing linearity in the 0–300 ms range and an exponential decrease in volume per unit time beyond this point; (<b>C</b>) correlation between the adjusted injection volume and the experimentally measured volume after calibration, demonstrating the accuracy of the system post-calibration.</p> Full article ">Figure 6

<p>Performance assessment of the developed temperature-programmable oven: (<b>a</b>) example of temperature control during an isothermal run at 60 °C; (<b>b</b>) correspondence between the temperature set by the user and the experimentally measured temperature; (<b>c</b>) relationship between the heating power required and the temperature ramp slope (°C/min); (<b>d</b>) an example of the oven’s operation during a run includes both isothermal and temperature gradient segments.</p> Full article ">Figure 7

<p>Chromatograms obtained using both the commercial microcell (Shimadzu) and the capillary cell developed in this work. The analysis was performed using a lab-made C-18 250 µm i.d ×150 mm packed column and a flow rate of 3.0 μL/min, with an injection volume of 60 nL. The elution order of the analytes was as follows: (1) naphthalene, (2) phenanthrene, and (3) anthracene. The concentration of each analyte was 30 mg/L.</p> Full article ">Figure 8

<p>Graphs showing variation as a function of the squared retention volume for the (<b>a</b>) lab-made and (<b>b</b>) commercial instruments.</p> Full article ">Figure 9

<p>Separation of PAHs (50 mg/mL) on a packed C18 capillary column (14 cm length, 250 µm i.d., 3.5 µm particle size) at a flow rate of 5.0 µL/min, using acetonitrile (70:30) as the mobile phase, under two conditions: (<b>a</b>) isothermal mode (no temperature programming) and (<b>b</b>) with temperature programming. Analytes: naphthalene (1), acenaphthylene (2), acenaphthene (3), fluorene (4), phenanthrene (5), anthracene (6), chrysene (7), and dibenzo(a,h)anthracene (8).</p> Full article ">Figure 10

<p>Separating alkylbenzene compounds using a WCOT column (5 m length, 50 μm i.d.): (<b>a</b>) without temperature programming and (<b>b</b>) with temperature programming. Peaks: uracil (1), Toluene (2), ethylbenzene (3), butylbenzene (4), pentylbenzene (5), and heptylbenzene (6).</p> Full article ">Figure 11

<p>Separating alkylbenzene compounds using a PLOT column (5 m length, 50 μm i.d.): (<b>a</b>) without temperature programming and (<b>b</b>) with temperature programming. Peaks: uracil (1), toluene (2), ethylbenzene (3), butylbenzene (4), pentylbenzene (5), and heptylbenzene (6).</p> Full article ">

Open AccessReview

Advances in Recycling Technologies of Critical Metals and Resources from Cathodes and Anodes in Spent Lithium-Ion Batteries

by

Shuwen Wang, Yanrong Lai, Jingran Yang, Jiaxue Zhao, Yushan Zhang, Miaoling Chen, Jinfeng Tang, Junhua Xu and Minhua Su

Separations 2025, 12(1), 4; https://doi.org/10.3390/separations12010004 - 30 Dec 2024

Abstract

With the rapid economic development and the continuous growth in the demand for new energy vehicles and energy storage systems, a significant number of waste lithium-ion batteries are expected to enter the market in the future. Effectively managing the processing and recycling of

[...] Read more.

With the rapid economic development and the continuous growth in the demand for new energy vehicles and energy storage systems, a significant number of waste lithium-ion batteries are expected to enter the market in the future. Effectively managing the processing and recycling of these batteries to minimize environmental pollution is a major challenge currently facing the lithium-ion battery industry. This paper analyzes and compares the recycling strategies for different components of lithium-ion batteries, providing a summary of the main types of batteries, existing technologies at various pre-treatment stages, and recycling techniques for valuable resources such as heavy metals and graphite. Currently, pyrometallurgy and hydrometallurgy processes have matured; however, their high energy consumption and pollution levels conflict with the principles of the current green economy. As a result, innovative technologies have emerged, aiming to reduce energy consumption while achieving high recovery rates and minimizing the environmental impact. Nevertheless, most of these technologies are currently limited to the laboratory scale and are not yet suitable for large-scale application.

Full article

(This article belongs to the Section Purification Technology)

►▼

Show Figures

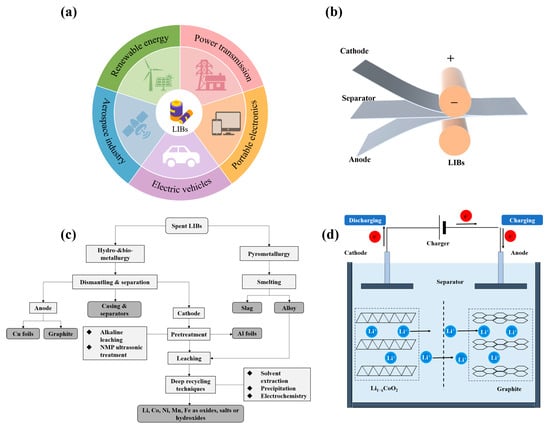

Figure 1

Figure 1

<p>(<b>a</b>) Applications of lithium-ion batteries; (<b>b</b>) The shape and components of some Li-ion battery configurations; (<b>c</b>) Flow-chart showing the typical recycling process; (<b>d</b>) Schematic diagram of the LIB working principle.</p> Full article ">Figure 2

<p>Schematic diagrams of pyrometallurgy, hydrometallurgy, and direct recovery processes [<a href="#B48-separations-12-00004" class="html-bibr">48</a>].</p> Full article ">Figure 3

<p>Characteristics of different pyrometallurgical technologies used to treat spent LIBs for the recovery of strategic metals.</p> Full article ">

<p>(<b>a</b>) Applications of lithium-ion batteries; (<b>b</b>) The shape and components of some Li-ion battery configurations; (<b>c</b>) Flow-chart showing the typical recycling process; (<b>d</b>) Schematic diagram of the LIB working principle.</p> Full article ">Figure 2

<p>Schematic diagrams of pyrometallurgy, hydrometallurgy, and direct recovery processes [<a href="#B48-separations-12-00004" class="html-bibr">48</a>].</p> Full article ">Figure 3

<p>Characteristics of different pyrometallurgical technologies used to treat spent LIBs for the recovery of strategic metals.</p> Full article ">

Open AccessArticle

CO2/CH4 and CO2/CO Selective Pebax-1657 Based Composite Hollow Fiber Membranes Prepared by a Novel Dip-Coating Technique

by

Dionysios S. Karousos, George V. Theodorakopoulos, Francesco Chiesa, Stéphan Barbe, Mirtat Bouroushian and Evangelos P. Favvas

Separations 2025, 12(1), 3; https://doi.org/10.3390/separations12010003 - 29 Dec 2024

Abstract

A novel and innovative method was developed to fabricate defect-free composite hollow fiber (HF) membranes using drop-casting under continuous flow. The synthesized Pebax-1657—based membranes were examined for gas separation processes, focusing on the separation of CO2 from CH4 and CO gases.

[...] Read more.

A novel and innovative method was developed to fabricate defect-free composite hollow fiber (HF) membranes using drop-casting under continuous flow. The synthesized Pebax-1657—based membranes were examined for gas separation processes, focusing on the separation of CO2 from CH4 and CO gases. The separation performance of the membranes was rigorously assessed under realistic binary gas mixture conditions to evaluate their selectivity and performance. The effect of pressure on separation performance was systematically investigated, with transmembrane pressures up to 10 bar being applied at a temperature of 298 K. Remarkable CO2/CH4 selectivities of up to 110 and CO2/CO selectivities of up to 48 were achieved, demonstrating the robustness and effectiveness of these composite HF membranes, suggesting their suitability for high-performance gas separation processes under varying operational conditions. Overall, this study introduces a novel approach for scaling up the fabrication of HF membranes and provides valuable insights into their application in CO2 separation technologies, offering the potential for advancements in areas such as natural gas processing and carbon capture from CO-containing streams.

Full article

(This article belongs to the Special Issue 10th Anniversary Special Issues: Membrane Separation Processes)

►▼

Show Figures

Figure 1

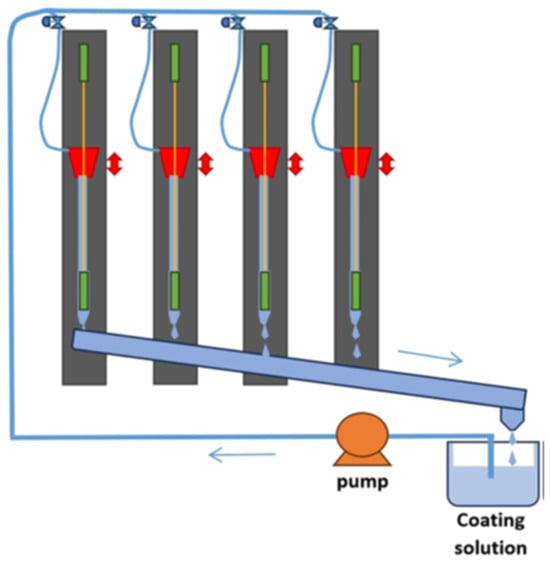

Figure 1

<p>Upscaled, according to a previous work [<a href="#B24-separations-12-00003" class="html-bibr">24</a>], HF coating device for underflow drop-casting.</p> Full article ">Figure 2

<p>SEM micrographs of the composite HF membrane: (<b>a</b>) cross-sectional view showing overall morphology; higher magnification images illustrating (<b>b</b>) the gutter layer; (<b>c</b>) the wall region with a sponge-like structure region; and (<b>d</b>) the separation layer thickness.</p> Full article ">Figure 3

<p>Separation factor (selectivity) and CO<sub>2</sub> permeance (GPU) as a function of pressure drop across the composite HF membrane for a gas mixture containing 10% <span class="html-italic">v</span>/<span class="html-italic">v</span> CO<sub>2</sub> in CH<sub>4</sub>. The temperature was maintained at 298 K.</p> Full article ">Figure 4

<p>Separation factor (selectivity) and CO<sub>2</sub> permeance (GPU) as a function of pressure drop across the composite HF membrane for a gas mixture containing 33% <span class="html-italic">v</span>/<span class="html-italic">v</span> CO<sub>2</sub> in CO. The temperature was maintained at 298 K.</p> Full article ">

<p>Upscaled, according to a previous work [<a href="#B24-separations-12-00003" class="html-bibr">24</a>], HF coating device for underflow drop-casting.</p> Full article ">Figure 2

<p>SEM micrographs of the composite HF membrane: (<b>a</b>) cross-sectional view showing overall morphology; higher magnification images illustrating (<b>b</b>) the gutter layer; (<b>c</b>) the wall region with a sponge-like structure region; and (<b>d</b>) the separation layer thickness.</p> Full article ">Figure 3

<p>Separation factor (selectivity) and CO<sub>2</sub> permeance (GPU) as a function of pressure drop across the composite HF membrane for a gas mixture containing 10% <span class="html-italic">v</span>/<span class="html-italic">v</span> CO<sub>2</sub> in CH<sub>4</sub>. The temperature was maintained at 298 K.</p> Full article ">Figure 4

<p>Separation factor (selectivity) and CO<sub>2</sub> permeance (GPU) as a function of pressure drop across the composite HF membrane for a gas mixture containing 33% <span class="html-italic">v</span>/<span class="html-italic">v</span> CO<sub>2</sub> in CO. The temperature was maintained at 298 K.</p> Full article ">

Open AccessArticle

Application of Magnetic Aquatic Plant Biochar for Efficient Removal of Antimony from Water: Adsorption Properties and Mechanism

by

Luyi Nan, Yuting Zhang, Min Liu, Liangyuan Zhao, Yuxuan Zhu and Xun Zhang

Separations 2025, 12(1), 2; https://doi.org/10.3390/separations12010002 - 28 Dec 2024

Abstract

Antimony (Sb) pollution in natural water bodies can cause significant harm to aquatic ecosystems. Currently, the utilization of chemicals in water bodies presents disadvantages, such as the hardship in collecting dispersed flocs and the incomplete elimination of pollutants. In the present research, a

[...] Read more.

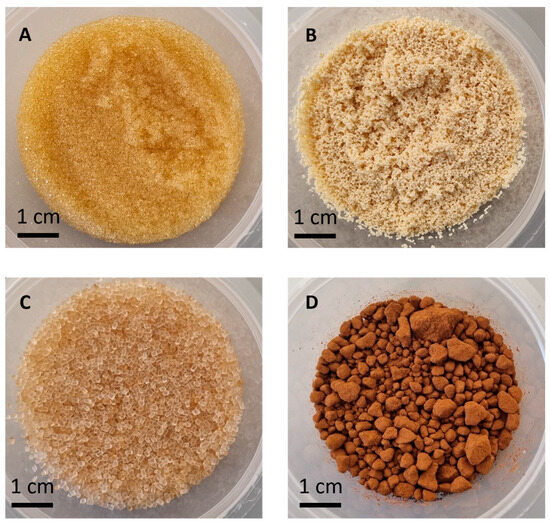

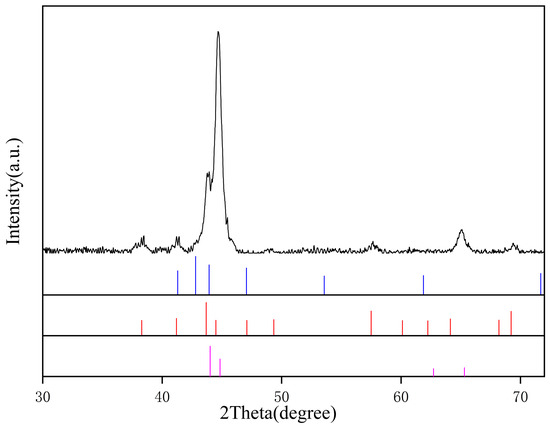

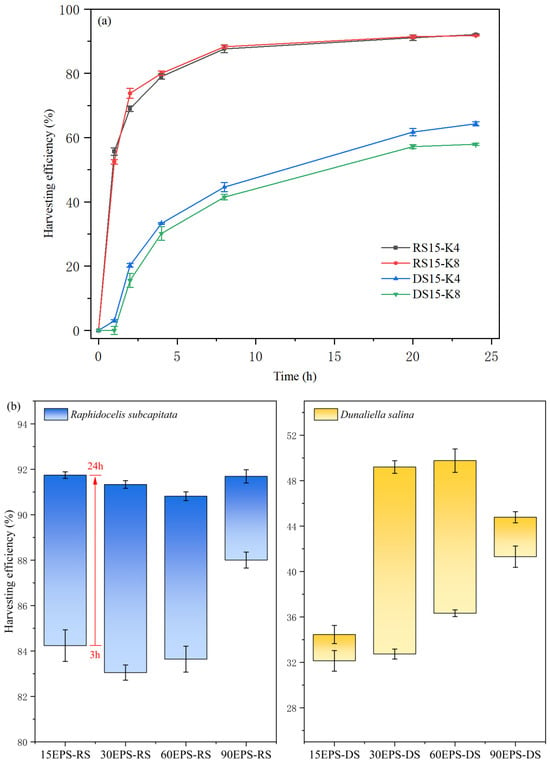

Antimony (Sb) pollution in natural water bodies can cause significant harm to aquatic ecosystems. Currently, the utilization of chemicals in water bodies presents disadvantages, such as the hardship in collecting dispersed flocs and the incomplete elimination of pollutants. In the present research, a novel type of efficient adsorbent material for the magnetic recovery of Sb was proposed: the magnetic aquatic plant biochar. Its adsorption characteristics and mechanism were deeply investigated. The results demonstrated that, among the three types of aquatic plants, the magnetic biochar of Arundo donax magnetic biochar (LMBC) displayed the most superior adsorption effect on Sb. Under optimal adsorption conditions (pyrolysis temperature of 300 °C, dosage of 100 mg, pH of 8), the removal rate of Sb by LMBC exceeded 97%. The adsorption rate of Sb by LMBC was relatively rapid, and the kinetics of adsorption conformed to a pseudo-second-order kinetic model. The adsorption isotherm was consistent with the Langmuir and Freundlich models, and the maximum adsorption capacity of Sb reached 26.07 mg/g, suggesting that the adsorption process pertained to the adsorption of multi-molecular layers. The influence of coexisting ions on the adsorption effect of LMBC was insignificant. The SEM characterization results revealed that LMBC mainly consisted of the elements C and O. The BET characterization results demonstrated that the magnetization modification augmented the specific surface area by approximately 30 times to reach 89.14 m2/g, and the pore volume increased by twofold to 0.18 cm3/g, creating a favorable condition for Sb adsorption. The FTIR, XRD, and XPS results indicated that the surface of LMBC was rich in carboxyl and hydroxyl groups and was successfully loaded with Fe2O3 and Fe3O4. LMBC not only facilitates the resourceful utilization of aquatic plant waste but also effectively removes antimony (Sb) pollution through its magnetic properties. This dual functionality presents promising application prospects for the efficient adsorption and removal of Sb from water.

Full article

(This article belongs to the Special Issue Adsorption of Emerging Water Pollutants by Advanced Materials)

►▼

Show Figures

Figure 1

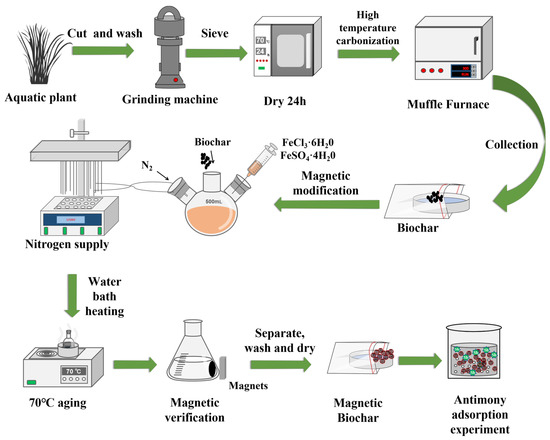

Figure 1

<p>The preparation process of the biochars and magnetic biochars.</p> Full article ">Figure 2

<p>Adsorption and desorption isothermal curves of LBC (<b>a</b>) and LMBC (<b>b</b>).</p> Full article ">Figure 3

<p>Scanning electron micrographs of LBC and LMBC before and after adsorption. (<b>a</b>) LBC-before adsorption; (<b>b</b>) LBC-after adsorption; (<b>c</b>) LMBC-before adsorption; (<b>d</b>) LMBC-after adsorption.</p> Full article ">Figure 4

<p>C, N, O, and Fe energy spectrum fluorescence of LBC and LMBC.</p> Full article ">Figure 5

<p>The FTlR results of LBC and LMBC before and after absorption.</p> Full article ">Figure 6

<p>XRD pattern of LBC and LMBC before and after adsorption.</p> Full article ">Figure 7

<p>XPS spectra of LMBC before and after adsorption. (<b>a</b>) Full spectrum; (<b>b</b>) C1s fine spectrum; (<b>c</b>) O1s fine spectrum; (<b>d</b>) Fe2p fine spectrum; and (<b>e</b>) Sb3d fine spectrum.</p> Full article ">Figure 7 Cont.

<p>XPS spectra of LMBC before and after adsorption. (<b>a</b>) Full spectrum; (<b>b</b>) C1s fine spectrum; (<b>c</b>) O1s fine spectrum; (<b>d</b>) Fe2p fine spectrum; and (<b>e</b>) Sb3d fine spectrum.</p> Full article ">Figure 8

<p>Magnetization curve of LMBC.</p> Full article ">Figure 9

<p>(<b>a</b>) Effect of biochar and magnetic biochar prepared by different aquatic plant species; (<b>b</b>) effect of biochar and magnetic biochar dosage; (<b>c</b>) effect of initial pH; and (<b>d</b>) effect of ionic strength. “****”: the number of asterisks denotes the level of statistical significance, with four asterisks indicating a <span class="html-italic">p</span>-value of less than 0.0001, signifying a highly significant difference between LBC and LMBC.</p> Full article ">Figure 10

<p>(<b>a</b>) Adsorption kinetics of LBC; (<b>b</b>) adsorption kinetics of LMBC; (<b>c</b>,<b>d</b>) adsorption isotherm of LBC; and (<b>e</b>,<b>f</b>) adsorption isotherm of LMBC (experimental conditions: 150 mL of 5 mg/L Sb solution with 100 mg LMBC at the initial pH of 8).</p> Full article ">Figure 11

<p>Schematic diagram of the mechanism of Sb adsorption and removal by LMBC.</p> Full article ">

<p>The preparation process of the biochars and magnetic biochars.</p> Full article ">Figure 2

<p>Adsorption and desorption isothermal curves of LBC (<b>a</b>) and LMBC (<b>b</b>).</p> Full article ">Figure 3

<p>Scanning electron micrographs of LBC and LMBC before and after adsorption. (<b>a</b>) LBC-before adsorption; (<b>b</b>) LBC-after adsorption; (<b>c</b>) LMBC-before adsorption; (<b>d</b>) LMBC-after adsorption.</p> Full article ">Figure 4

<p>C, N, O, and Fe energy spectrum fluorescence of LBC and LMBC.</p> Full article ">Figure 5

<p>The FTlR results of LBC and LMBC before and after absorption.</p> Full article ">Figure 6

<p>XRD pattern of LBC and LMBC before and after adsorption.</p> Full article ">Figure 7

<p>XPS spectra of LMBC before and after adsorption. (<b>a</b>) Full spectrum; (<b>b</b>) C1s fine spectrum; (<b>c</b>) O1s fine spectrum; (<b>d</b>) Fe2p fine spectrum; and (<b>e</b>) Sb3d fine spectrum.</p> Full article ">Figure 7 Cont.

<p>XPS spectra of LMBC before and after adsorption. (<b>a</b>) Full spectrum; (<b>b</b>) C1s fine spectrum; (<b>c</b>) O1s fine spectrum; (<b>d</b>) Fe2p fine spectrum; and (<b>e</b>) Sb3d fine spectrum.</p> Full article ">Figure 8

<p>Magnetization curve of LMBC.</p> Full article ">Figure 9

<p>(<b>a</b>) Effect of biochar and magnetic biochar prepared by different aquatic plant species; (<b>b</b>) effect of biochar and magnetic biochar dosage; (<b>c</b>) effect of initial pH; and (<b>d</b>) effect of ionic strength. “****”: the number of asterisks denotes the level of statistical significance, with four asterisks indicating a <span class="html-italic">p</span>-value of less than 0.0001, signifying a highly significant difference between LBC and LMBC.</p> Full article ">Figure 10

<p>(<b>a</b>) Adsorption kinetics of LBC; (<b>b</b>) adsorption kinetics of LMBC; (<b>c</b>,<b>d</b>) adsorption isotherm of LBC; and (<b>e</b>,<b>f</b>) adsorption isotherm of LMBC (experimental conditions: 150 mL of 5 mg/L Sb solution with 100 mg LMBC at the initial pH of 8).</p> Full article ">Figure 11

<p>Schematic diagram of the mechanism of Sb adsorption and removal by LMBC.</p> Full article ">

Open AccessArticle

Irradiated Gao Miao Zi Bentonite for Uranium Retention: Performance and Mechanism

by

Yushan Zhang, Gang Song, Yujie Mo, Shuwen Wang, Diyun Chen and Minhua Su

Separations 2025, 12(1), 1; https://doi.org/10.3390/separations12010001 - 26 Dec 2024

Abstract

Bentonite has been considered as backfill material in the long-term deep geological disposal sites for radioactive waste. The performance of raw and irradiated bentonite based on the retention of radioactive nuclides, such as U(VI), is a critical factor for its application. Herein, the

[...] Read more.

Bentonite has been considered as backfill material in the long-term deep geological disposal sites for radioactive waste. The performance of raw and irradiated bentonite based on the retention of radioactive nuclides, such as U(VI), is a critical factor for its application. Herein, the intrinsic features and adsorption behavior of Gao Miao Zi (GMZ) bentonite based on uranyl ions was investigated. In aqueous solutions, bentonite can achieve an adsorption rate of up to 100% for U(VI). The primary mechanism of U(VI) adsorption by GMZ bentonite is ion exchange, supplemented by surface complexation. Strong irradiation can introduce slight structural changes and framework fractures in bentonite, reducing its adsorption capacity for U(VI). This study provides an in-depth analysis of the adverse effects of high doses of radiation (100 kGy) on the microstructure and adsorption properties of bentonite, offering important insights for the safe storage of radioactive waste.

Full article

(This article belongs to the Special Issue Separation Technology for Metal Extraction and Removal)

►▼

Show Figures

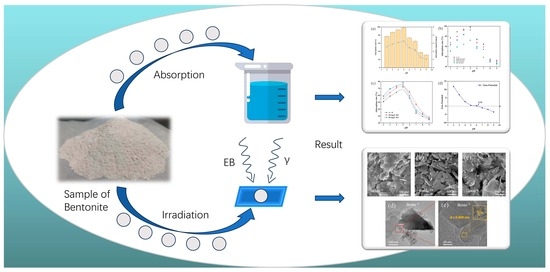

Graphical abstract

Graphical abstract

Full article ">Figure 1

<p>SEM images of (<b>a</b>) natural GMZ bentonite, (<b>b</b>) electron-beam-irradiated bentonite, and (<b>c</b>) gamma-irradiated bentonite, as well as (<b>d</b>) TEM image of natural GMZ bentonite and (<b>e</b>) TEM high-resolution image.</p> Full article ">Figure 2

<p>(<b>a</b>) The SEM elemental mapping images, (<b>b</b>) elemental composition, and (<b>c</b>) elemental content of the GMZ bentonite.</p> Full article ">Figure 3

<p>(<b>a</b>) XRD pattern, (<b>b</b>) FT-IR spectra, (<b>c</b>) N<sub>2</sub> adsorption-desorption isotherm, and (<b>d</b>) pore size distribution curve of GMZ bentonite before and after irradiation.</p> Full article ">Figure 4

<p>(<b>a</b>) Effect of the contact time and dosing amount on the uranium adsorption rate based on the adsorption of GMZ bentonite (uranium initial = 20 mg/L, pH = 5, T = room temperature); (<b>b</b>) effect of the initial uranium concentration on the absorption rate and adsorption capacity based on the adsorption of GMZ bentonite (dosage = 6 g/L, pH = 5, t = 30 min, and T = room temperature).</p> Full article ">Figure 5

<p>Effect of (<b>a</b>) pH (uranium initial = 20 mg/L, T = room temperature, m/V = 6 g/L); (<b>b</b>) ionic strength (uranium initial = 20 mg/L, T = room temperature, m/V = 6 g/L); (<b>c</b>) HA concentration (uranium initial = 20 mg/L, T = room temperature, m/V = 6 g/L, I = 0.1 M NaCl); (<b>d</b>) zeta potentials of bentonite as a function of pH (uranium initial = 20 mg/L, T = room temperature, m/V = 6 g/L).</p> Full article ">Figure 6

<p>(<b>a</b>) Kinetic model; (<b>b</b>) particle diffusion model; (<b>c</b>) isothermal model of GMZ bentonite for the adsorption of uranium.</p> Full article ">Figure 7

<p>(<b>a</b>) TEM, (<b>b</b>) TEM-EDS, (<b>c</b>) XRD, (<b>d</b>) FT-IR, and (<b>e</b>) XPS full-survey spectra, as well as the (<b>f</b>) U 4f XPS spectra of the GMZ bentonite before and after the absorption of U(VI).</p> Full article ">Figure 8

<p>The possible mechanism of uranium adsorption by GMZ bentonite.</p> Full article ">

Full article ">Figure 1

<p>SEM images of (<b>a</b>) natural GMZ bentonite, (<b>b</b>) electron-beam-irradiated bentonite, and (<b>c</b>) gamma-irradiated bentonite, as well as (<b>d</b>) TEM image of natural GMZ bentonite and (<b>e</b>) TEM high-resolution image.</p> Full article ">Figure 2

<p>(<b>a</b>) The SEM elemental mapping images, (<b>b</b>) elemental composition, and (<b>c</b>) elemental content of the GMZ bentonite.</p> Full article ">Figure 3

<p>(<b>a</b>) XRD pattern, (<b>b</b>) FT-IR spectra, (<b>c</b>) N<sub>2</sub> adsorption-desorption isotherm, and (<b>d</b>) pore size distribution curve of GMZ bentonite before and after irradiation.</p> Full article ">Figure 4

<p>(<b>a</b>) Effect of the contact time and dosing amount on the uranium adsorption rate based on the adsorption of GMZ bentonite (uranium initial = 20 mg/L, pH = 5, T = room temperature); (<b>b</b>) effect of the initial uranium concentration on the absorption rate and adsorption capacity based on the adsorption of GMZ bentonite (dosage = 6 g/L, pH = 5, t = 30 min, and T = room temperature).</p> Full article ">Figure 5

<p>Effect of (<b>a</b>) pH (uranium initial = 20 mg/L, T = room temperature, m/V = 6 g/L); (<b>b</b>) ionic strength (uranium initial = 20 mg/L, T = room temperature, m/V = 6 g/L); (<b>c</b>) HA concentration (uranium initial = 20 mg/L, T = room temperature, m/V = 6 g/L, I = 0.1 M NaCl); (<b>d</b>) zeta potentials of bentonite as a function of pH (uranium initial = 20 mg/L, T = room temperature, m/V = 6 g/L).</p> Full article ">Figure 6

<p>(<b>a</b>) Kinetic model; (<b>b</b>) particle diffusion model; (<b>c</b>) isothermal model of GMZ bentonite for the adsorption of uranium.</p> Full article ">Figure 7

<p>(<b>a</b>) TEM, (<b>b</b>) TEM-EDS, (<b>c</b>) XRD, (<b>d</b>) FT-IR, and (<b>e</b>) XPS full-survey spectra, as well as the (<b>f</b>) U 4f XPS spectra of the GMZ bentonite before and after the absorption of U(VI).</p> Full article ">Figure 8

<p>The possible mechanism of uranium adsorption by GMZ bentonite.</p> Full article ">

Open AccessArticle

The Effect of Plasma Pretreatment on the Flotation of Lithium Aluminate and Gehlenite Using Light-Switchable Collectors

by

Ali Zgheib, Maximilian Hans Fischer, Stéphanie Mireille Tsanang, Iliass El Hraoui, Shukang Zhang, Annett Wollmann, Alfred P. Weber, Ursula E. A. Fittschen, Thomas Schirmer and Andreas Schmidt

Separations 2024, 11(12), 362; https://doi.org/10.3390/separations11120362 - 23 Dec 2024

Abstract

The pyridinium phenolate punicine is a switchable molecule from Punica granatum. Depending on the pH, punicine exists as a cation, neutral molecule, anion, or dianion. In addition, punicine reacts to light, under the influence of which it forms radical species. We report

[...] Read more.

The pyridinium phenolate punicine is a switchable molecule from Punica granatum. Depending on the pH, punicine exists as a cation, neutral molecule, anion, or dianion. In addition, punicine reacts to light, under the influence of which it forms radical species. We report on three punicine derivatives that possess an adamantyl, 2-methylnonyl, or heptadecyl substituent and on their performance in the flotation of lithium aluminate, an engineered artificial mineral (EnAM) for the recycling of lithium, e.g., from lithium-ion batteries. By optimizing the parameters: pH and light conditions (daylight, darkness), recovery rates of 92% of LiAlO2 are achieved. In all cases, the flotation of the gangue material gehlenite (Ca2Al[AlSiO7]) is suppressed. IR, the contact angle, zeta potential measurements, TG-MS, and PXRD confirm that the punicines interact with the surface of LiAlO2, which is covered by LiAl2(OH)7 after contact to water, resulting in a hydrophobization of the particle. The plasma pretreatment of the lithium aluminate has a significant influence on the flotation results and increases the recovery rates of lithium aluminate in blank tests by 58%. The oxidative plasma leads to a partial dehydratisation of the LiAl2(OH)7 and thus to a hydrophobization of the particles, while a reductive plasma causes a more hydrophilic particle surface.

Full article

(This article belongs to the Special Issue Green Separation and Purification Technology)

►▼

Show Figures

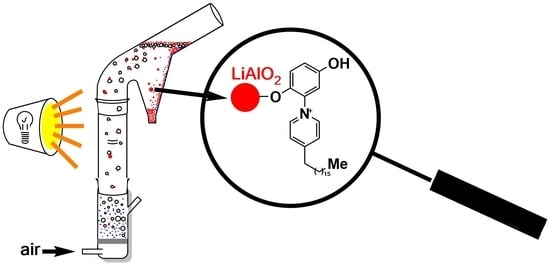

Graphical abstract

Graphical abstract

Full article ">Figure 1

<p>TGA measurements of pure lithium aluminate and 5 min oxidative plasma-pretreated lithium aluminate samples.</p> Full article ">Figure 2

<p>TG-MS of pure LiAlO<sub>2</sub> (<b>left</b>) and 5 min plasma pretreated LiAlO<sub>2</sub> (<b>right</b>).</p> Full article ">Figure 3

<p>Comparison of the recovery rates of lithium aluminate at different light scenarios in the presence of the collectors <b>1</b>–<b>3</b> under identical conditions, i.e., 2.00 g of LiAlO<sub>2</sub>, 1 min of mixing (500 rpm) with 25 mL of distilled water, 60 µL (1 × 10<sup>−5</sup> M) of the corresponding collector, 1 min of mixing, 30 µL of frother, and another 1 min of mixing. The flotation was done for 3 min at an air flow rate of 32 mL/min using 250 mL distilled water in daylight at a pH of 10.9 ± 0.3.</p> Full article ">Figure 4

<p>Comparison of the recovery rates of lithium aluminate at different pH values in the presence of the collectors <b>1</b>–<b>3</b> under identical conditions, i.e., 2.00 g of LiAlO<sub>2</sub>, 1 min of mixing (500 rpm) with 25 mL of distilled water, 60 µL (1 × 10<sup>−5</sup> M) of the corresponding collector, 1 min of mixing, 30 µL of frother, and another 1 min of mixing. The flotation was done for 3 min at an air flow rate of 32 mL/min using 250 mL distilled water in daylight.</p> Full article ">Figure 5

<p>Single mineral flotation of lithium aluminate and gehlenite using punicine <b>3</b> as collector at pH 10.9 ± 0.3 for lithium aluminate and pH 8.3 ± 0.3 for gehlenite at different light scenarios. The conditioning was as follows: 120 µL collector, 1 min mixing, 30 µL frother, 1 min mixing, stirring speed 500 rpm, air flow rate of 32 cm<sup>3</sup>/min using 250 mL distilled water, and flotation time of 3 min.</p> Full article ">Figure 6

<p>Single mineral flotation of plasma-pretreated lithium aluminate and the gehlenite-rich material without collector at pH 10.9 ± 0.3 for lithium aluminate and pH 8.3 ± 0.3 for gehlenite as a function of plasma treatment time. Conditioning was as follows: 30 µL frother, 1 min mixing, stirring speed 500 rpm, air flow rate of 32 cm<sup>3</sup>/min using 250 mL distilled water, and flotation time of 3 min.</p> Full article ">Figure 7

<p>Single mineral flotation of the oxidative plasma pretreated lithium aluminate and gehlenite using punicine <b>3</b> as a collector at pH 10.9 ± 0.3 for lithium aluminate, and pH 8.3 for gehlenite as a function of plasma treatment time in min. The conditioning was as follows: 60 µL collector, 1 min mixing 30 µL frother, 1 min mixing, stirring speed of 500 rpm, air flow rate of 32 cm<sup>3</sup>/min using 250 mL distilled water, and applying a flotation time of 3 min.</p> Full article ">Figure 8

<p>Single mineral flotation of the reductive plasma pretreated lithium aluminate in blank and using punicine <b>3</b> as a collector at pH 10.9 ± 0.3 as a function of plasma treatment time in min. The conditioning was as follows: 60 µL collector, 1 min mixing 30 µL frother, 1 min mixing, stirring speed of 500 rpm, air flow rate of 32 cm<sup>3</sup>/min using 250 mL distilled water, and flotation time of 3 min.</p> Full article ">Figure 9

<p>Contact angle on LiAlO<sub>2</sub> before and after flotation with punicine <b>3</b> under identical conditions, i.e., 2.00 g of the mineral, 1 min mixing (500 rpm) with 25 mL distilled water, 120 µL (2 × 10<sup>−5</sup> M) of the corresponding collector, 1 min mixing, 30 µL foaming agent, and 1 min mixing again. Flotation was carried out for 3 min at an air flow rate of 32 mL/min with 250 mL of distilled water in daylight and a pH of 10.9 ± 0.3.</p> Full article ">Figure 10

<p>Zeta potential of pure lithium aluminate, lithium aluminate with 7.2 µL of 42.5 mmol/L punicine <b>1</b>, lithium aluminate with 7.2 µL of 42.5 mmol/L punicine <b>2,</b> and lithium aluminate with 7.2 µL of 42.5 mmol/L punicine <b>3</b> in distilled water and under different pH values.</p> Full article ">Figure 11

<p>FTIR spectra of LiAlO<sub>2</sub> in the presence of 60 µL 42.5 µmol/L punicine <b>3</b> with and without pretreatment with plasma.</p> Full article ">Figure 12

<p>Zeta potential of pure and oxidative plasma-pretreated lithium aluminate, with and without 10 µL of 42.5 mmol/L punicine <b>3</b> at pH 10.9 ± 0.3.</p> Full article ">Scheme 1

<p>Schematic representation of the switchability of punicine with respect to charges and radical status.</p> Full article ">Scheme 2

<p>Intermolecular interactions and complexes of punicine.</p> Full article ">Scheme 3

<p>Synthesis of the punicine derivatives.</p> Full article ">Scheme 4

<p>Reactions of lithium aluminate surfaces with water.</p> Full article ">Scheme 5

<p>Interactions of punicines with lithium aluminum surfaces.</p> Full article ">

Full article ">Figure 1

<p>TGA measurements of pure lithium aluminate and 5 min oxidative plasma-pretreated lithium aluminate samples.</p> Full article ">Figure 2

<p>TG-MS of pure LiAlO<sub>2</sub> (<b>left</b>) and 5 min plasma pretreated LiAlO<sub>2</sub> (<b>right</b>).</p> Full article ">Figure 3

<p>Comparison of the recovery rates of lithium aluminate at different light scenarios in the presence of the collectors <b>1</b>–<b>3</b> under identical conditions, i.e., 2.00 g of LiAlO<sub>2</sub>, 1 min of mixing (500 rpm) with 25 mL of distilled water, 60 µL (1 × 10<sup>−5</sup> M) of the corresponding collector, 1 min of mixing, 30 µL of frother, and another 1 min of mixing. The flotation was done for 3 min at an air flow rate of 32 mL/min using 250 mL distilled water in daylight at a pH of 10.9 ± 0.3.</p> Full article ">Figure 4

<p>Comparison of the recovery rates of lithium aluminate at different pH values in the presence of the collectors <b>1</b>–<b>3</b> under identical conditions, i.e., 2.00 g of LiAlO<sub>2</sub>, 1 min of mixing (500 rpm) with 25 mL of distilled water, 60 µL (1 × 10<sup>−5</sup> M) of the corresponding collector, 1 min of mixing, 30 µL of frother, and another 1 min of mixing. The flotation was done for 3 min at an air flow rate of 32 mL/min using 250 mL distilled water in daylight.</p> Full article ">Figure 5

<p>Single mineral flotation of lithium aluminate and gehlenite using punicine <b>3</b> as collector at pH 10.9 ± 0.3 for lithium aluminate and pH 8.3 ± 0.3 for gehlenite at different light scenarios. The conditioning was as follows: 120 µL collector, 1 min mixing, 30 µL frother, 1 min mixing, stirring speed 500 rpm, air flow rate of 32 cm<sup>3</sup>/min using 250 mL distilled water, and flotation time of 3 min.</p> Full article ">Figure 6

<p>Single mineral flotation of plasma-pretreated lithium aluminate and the gehlenite-rich material without collector at pH 10.9 ± 0.3 for lithium aluminate and pH 8.3 ± 0.3 for gehlenite as a function of plasma treatment time. Conditioning was as follows: 30 µL frother, 1 min mixing, stirring speed 500 rpm, air flow rate of 32 cm<sup>3</sup>/min using 250 mL distilled water, and flotation time of 3 min.</p> Full article ">Figure 7

<p>Single mineral flotation of the oxidative plasma pretreated lithium aluminate and gehlenite using punicine <b>3</b> as a collector at pH 10.9 ± 0.3 for lithium aluminate, and pH 8.3 for gehlenite as a function of plasma treatment time in min. The conditioning was as follows: 60 µL collector, 1 min mixing 30 µL frother, 1 min mixing, stirring speed of 500 rpm, air flow rate of 32 cm<sup>3</sup>/min using 250 mL distilled water, and applying a flotation time of 3 min.</p> Full article ">Figure 8

<p>Single mineral flotation of the reductive plasma pretreated lithium aluminate in blank and using punicine <b>3</b> as a collector at pH 10.9 ± 0.3 as a function of plasma treatment time in min. The conditioning was as follows: 60 µL collector, 1 min mixing 30 µL frother, 1 min mixing, stirring speed of 500 rpm, air flow rate of 32 cm<sup>3</sup>/min using 250 mL distilled water, and flotation time of 3 min.</p> Full article ">Figure 9

<p>Contact angle on LiAlO<sub>2</sub> before and after flotation with punicine <b>3</b> under identical conditions, i.e., 2.00 g of the mineral, 1 min mixing (500 rpm) with 25 mL distilled water, 120 µL (2 × 10<sup>−5</sup> M) of the corresponding collector, 1 min mixing, 30 µL foaming agent, and 1 min mixing again. Flotation was carried out for 3 min at an air flow rate of 32 mL/min with 250 mL of distilled water in daylight and a pH of 10.9 ± 0.3.</p> Full article ">Figure 10

<p>Zeta potential of pure lithium aluminate, lithium aluminate with 7.2 µL of 42.5 mmol/L punicine <b>1</b>, lithium aluminate with 7.2 µL of 42.5 mmol/L punicine <b>2,</b> and lithium aluminate with 7.2 µL of 42.5 mmol/L punicine <b>3</b> in distilled water and under different pH values.</p> Full article ">Figure 11

<p>FTIR spectra of LiAlO<sub>2</sub> in the presence of 60 µL 42.5 µmol/L punicine <b>3</b> with and without pretreatment with plasma.</p> Full article ">Figure 12

<p>Zeta potential of pure and oxidative plasma-pretreated lithium aluminate, with and without 10 µL of 42.5 mmol/L punicine <b>3</b> at pH 10.9 ± 0.3.</p> Full article ">Scheme 1

<p>Schematic representation of the switchability of punicine with respect to charges and radical status.</p> Full article ">Scheme 2

<p>Intermolecular interactions and complexes of punicine.</p> Full article ">Scheme 3

<p>Synthesis of the punicine derivatives.</p> Full article ">Scheme 4

<p>Reactions of lithium aluminate surfaces with water.</p> Full article ">Scheme 5

<p>Interactions of punicines with lithium aluminum surfaces.</p> Full article ">

Open AccessArticle

Modified Biochar Adsorption Combined with Alkaline Solution Absorption for Sulfur-Containing Odor Gases Removal from Domestic Waste Transfer Stations

by

Wei Wei, Ningjie Wang and Xiaolei Zhang

Separations 2024, 11(12), 361; https://doi.org/10.3390/separations11120361 - 23 Dec 2024

Abstract

Odor emission has become a major issue in waste transfer stations. Hydrogen sulfide, methyl mercaptan (MM), and dimethyl disulfide (DMDS) are the main odorous gases. They have a low odor threshold and are difficult to remove. In this study, pine bark biochar was

[...] Read more.

Odor emission has become a major issue in waste transfer stations. Hydrogen sulfide, methyl mercaptan (MM), and dimethyl disulfide (DMDS) are the main odorous gases. They have a low odor threshold and are difficult to remove. In this study, pine bark biochar was produced and modified with metal ions, including Ni2+, Ti2+, Mn2+, Zn2+, Mg2+, and Cu2+. It was then used for the removal of hydrogen sulfide, methyl mercaptan, and dimethyl disulfide. Among all modifications, the Cu2+ modified biochar showed the best sorption capacity, and the maximum sorption amounts were 20.50 mg/g for H2S, 36.50 mg/g for MM, and 57.98 mg/g for DMDS. To understand the adsorption, BET, SEM, and XPS of the original and modified biochar were performed. This illustrated that modification with Cu2+ increased the surface area and porosity, thus enhancing the adsorption capacity. In the alkaline absorption study, it was found that the removal of the three odor gases increased with the pH increase. Based on the results, a combined process called absorption–adsorption was established to treat the odor gas generated in a local waste transfer station. Thirty-one gas components were detected in the odor gas of the waste transfer station. The process proceeded for 30 days, and these gas components were not found in the effluent during treatment. Regarding H2S, MM, and DMDS, they were not detected even after 90 days. This indicates the high adsorption capacity of the modified biochar toward the three odor gases. In addition, the process is simple and easy to operate. This suggests that it is suitable for treating odor in places where there is no technician, and the odor needs efficient treatment. The study provides a feasible alternative for domestic waste transfer stations to control the odor problem.

Full article

(This article belongs to the Topic Advances in Separation Engineering)

►▼

Show Figures

Figure 1

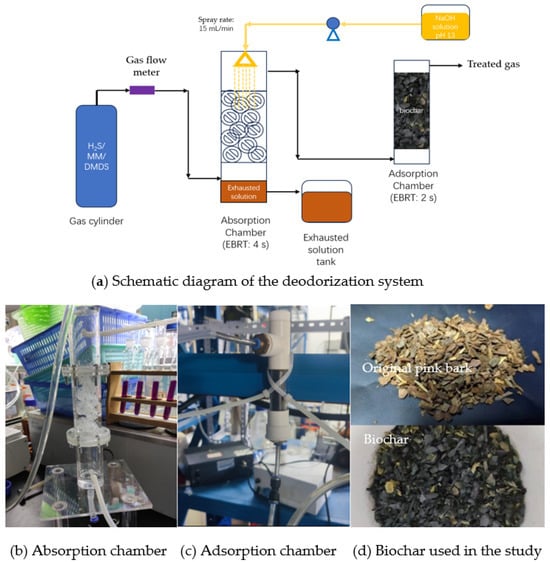

Figure 1

<p>The deodorization system employed for the removal of H<sub>2</sub>S, MM, and DMDS.</p> Full article ">Figure 2

<p>Removal of odor gases by chemical absorption under different conditions: (<b>a</b>) Scrubbing solution pH; (<b>b</b>) Empty bed residence time of the reactor; and (<b>c</b>) NaOH solution dosage.</p> Full article ">Figure 2 Cont.

<p>Removal of odor gases by chemical absorption under different conditions: (<b>a</b>) Scrubbing solution pH; (<b>b</b>) Empty bed residence time of the reactor; and (<b>c</b>) NaOH solution dosage.</p> Full article ">Figure 3

<p>Biochar adsorption capacity: (<b>a</b>) Biochar modified with different metal ions; (<b>b</b>) Biochar modified with various concentrations of Cu<sup>2+</sup>; (<b>c</b>) Cu<sup>2+</sup>-modified biochar obtained at different combustion temperatures.</p> Full article ">Figure 3 Cont.

<p>Biochar adsorption capacity: (<b>a</b>) Biochar modified with different metal ions; (<b>b</b>) Biochar modified with various concentrations of Cu<sup>2+</sup>; (<b>c</b>) Cu<sup>2+</sup>-modified biochar obtained at different combustion temperatures.</p> Full article ">Figure 4

<p>Characteristics of the original and modified biochar: (<b>a</b>) Nitrogen adsorption–desorption curve of biochar; (<b>b</b>) Pore size distribution from 0 to 300 nm; (<b>c</b>) Pore size distribution on a smaller scale compared to (<b>b</b>), which is from 0 to 4 nm.</p> Full article ">Figure 5

<p>SEM analysis of the original and Cu<sup>2+</sup>-modified biochar.</p> Full article ">Figure 5 Cont.

<p>SEM analysis of the original and Cu<sup>2+</sup>-modified biochar.</p> Full article ">Figure 6

<p>The XPS spectra of elements in the modified biochar before and after utilization in adsorption. (<b>a</b>,<b>b</b>) Original biochar with the appearance of observed elements; (<b>c</b>–<b>e</b>) Biochar after utilization in adsorption of H<sub>2</sub>S, MM, and DMDS, respectively.</p> Full article ">

<p>The deodorization system employed for the removal of H<sub>2</sub>S, MM, and DMDS.</p> Full article ">Figure 2

<p>Removal of odor gases by chemical absorption under different conditions: (<b>a</b>) Scrubbing solution pH; (<b>b</b>) Empty bed residence time of the reactor; and (<b>c</b>) NaOH solution dosage.</p> Full article ">Figure 2 Cont.

<p>Removal of odor gases by chemical absorption under different conditions: (<b>a</b>) Scrubbing solution pH; (<b>b</b>) Empty bed residence time of the reactor; and (<b>c</b>) NaOH solution dosage.</p> Full article ">Figure 3

<p>Biochar adsorption capacity: (<b>a</b>) Biochar modified with different metal ions; (<b>b</b>) Biochar modified with various concentrations of Cu<sup>2+</sup>; (<b>c</b>) Cu<sup>2+</sup>-modified biochar obtained at different combustion temperatures.</p> Full article ">Figure 3 Cont.

<p>Biochar adsorption capacity: (<b>a</b>) Biochar modified with different metal ions; (<b>b</b>) Biochar modified with various concentrations of Cu<sup>2+</sup>; (<b>c</b>) Cu<sup>2+</sup>-modified biochar obtained at different combustion temperatures.</p> Full article ">Figure 4

<p>Characteristics of the original and modified biochar: (<b>a</b>) Nitrogen adsorption–desorption curve of biochar; (<b>b</b>) Pore size distribution from 0 to 300 nm; (<b>c</b>) Pore size distribution on a smaller scale compared to (<b>b</b>), which is from 0 to 4 nm.</p> Full article ">Figure 5

<p>SEM analysis of the original and Cu<sup>2+</sup>-modified biochar.</p> Full article ">Figure 5 Cont.

<p>SEM analysis of the original and Cu<sup>2+</sup>-modified biochar.</p> Full article ">Figure 6

<p>The XPS spectra of elements in the modified biochar before and after utilization in adsorption. (<b>a</b>,<b>b</b>) Original biochar with the appearance of observed elements; (<b>c</b>–<b>e</b>) Biochar after utilization in adsorption of H<sub>2</sub>S, MM, and DMDS, respectively.</p> Full article ">

Open AccessArticle

Ion Activity Coefficient of Sodium Halides in Anion-Exchange Polymers: Empirical Model Based on Manning’s Counterion Condensation Theory

by

Guiming Liu and Dandan Gao

Separations 2024, 11(12), 360; https://doi.org/10.3390/separations11120360 - 23 Dec 2024

Abstract

The theory of electrolyte solution provides a precise description of the thermodynamic state and non-ideality of electrolyte solutions, allowing for the accurate prediction of the crystallization separation process of Salt Lake brine. Analogously, we attempt to describe the non-ideality of ions in ion-exchange

[...] Read more.

The theory of electrolyte solution provides a precise description of the thermodynamic state and non-ideality of electrolyte solutions, allowing for the accurate prediction of the crystallization separation process of Salt Lake brine. Analogously, we attempt to describe the non-ideality of ions in ion-exchange polymers based on Manning’s Counterion Condensation Theory, which was originally used to describe the thermodynamics of polyelectrolyte solutions, has amply proven the potential to extend to ion-exchange polymers. In this article, equilibrium solvent and solute concentrations in aminated cross-linked polystyrene AEM were determined experimentally as a function of external NaCl concentration, and ion activity coefficients in the membranes were obtained via a thermodynamic treatment. With the recombination and empirical parameters added to Manning’s model, the ion activity coefficient of NaCl and NaBr in the aminated cross-linked polystyrene AEM can be accurately described in concentration ranges of 0.01 mol·kg−1~3 mol·kg−1. Compared with the original model, the Coefficient of Determination between the improved model and the experimental data was increased from 0.65 to 0.95. The Residual Sum of Squares is reduced by about one order of magnitude, significantly improving the Manning model’s adaptability when applied to AEM.

Full article

(This article belongs to the Special Issue Green and Efficient Separation and Extraction of Salt Lake Resources)

►▼

Show Figures

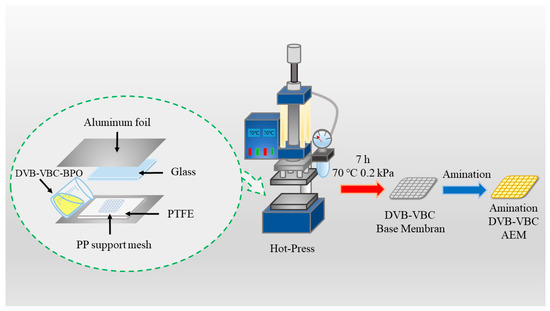

Figure 1

Figure 1

<p>The process for preparing aminated cross-linked polystyrene (ACLP) involves bulk polymerization followed by amination [<a href="#B43-separations-11-00360" class="html-bibr">43</a>].</p> Full article ">Figure 2

<p>The “equilibrium–desorption–exchange” step was employed to measure concentrations within the AEM [<a href="#B10-separations-11-00360" class="html-bibr">10</a>], as illustrated by the different colors in this figure. After the AEM reached swelling equilibrium in the solution, the internal co-ions (Na<sup>+</sup>) and some counter-ions (Cl<sup>−</sup>, Br<sup>−</sup>) contributed by mobile electrolytes could be determined through multiple desorptions of secondary water. Subsequently, the electrostatically bound counter-ions on the fixed groups were exchanged with a 0.1 mol·L<sup>−</sup><sup>1</sup> Na<sub>2</sub>SO<sub>4</sub> solution.</p> Full article ">Figure 3

<p>The influence of external solution molality and cross-linking on the water uptake of ACLP AEMs (excluding the internal PP fiber) is significant. Water uptake decreases with increasing external solution molality and cross-linking. The water uptake values are reported as the mass of water per unit mass of the ion-exchange polymer in the membrane.</p> Full article ">Figure 4

<p>The molal concentrations of co-ions, <math display="inline"><semantics> <mrow> <msubsup> <mrow> <mi mathvariant="italic">m</mi> </mrow> <mrow> <msup> <mrow> <mi>Na</mi> </mrow> <mrow> <mo>+</mo> </mrow> </msup> </mrow> <mrow> <mi mathvariant="normal">m</mi> </mrow> </msubsup> </mrow> </semantics></math>, and counter-ions, <math display="inline"><semantics> <mrow> <msubsup> <mrow> <mi mathvariant="italic">m</mi> </mrow> <mrow> <msup> <mrow> <mi mathvariant="normal">X</mi> </mrow> <mrow> <mo>−</mo> </mrow> </msup> </mrow> <mrow> <mi mathvariant="normal">m</mi> </mrow> </msubsup> <mtext> </mtext> </mrow> </semantics></math> (X = Cl, Br), in the anion-exchange polymer are presented as a function of external electrolyte concentration for NaCl (<b>a</b>,<b>b</b>) and NaBr (<b>c</b>,<b>d</b>).</p> Full article ">Figure 5

<p>The influence of external electrolyte concentration <math display="inline"><semantics> <mrow> <msubsup> <mrow> <mi mathvariant="italic">m</mi> </mrow> <mrow> <mi>NaX</mi> </mrow> <mrow> <mi mathvariant="normal">s</mi> </mrow> </msubsup> </mrow> </semantics></math> on the activity coefficients of the membrane in NaCl (<b>a</b>) and NaBr (<b>b</b>) is presented and obtained experimentally via Equation (10). Additionally, the respective ionic activity coefficients of the co-ions <math display="inline"><semantics> <mrow> <msubsup> <mrow> <mo mathvariant="italic">γ</mo> </mrow> <mrow> <msup> <mrow> <mi>Na</mi> </mrow> <mrow> <mo>+</mo> </mrow> </msup> </mrow> <mrow> <mi mathvariant="normal">m</mi> </mrow> </msubsup> </mrow> </semantics></math> (<b>c</b>) and counter-ions <math display="inline"><semantics> <mrow> <msubsup> <mrow> <mo mathvariant="italic">γ</mo> </mrow> <mrow> <msup> <mrow> <mi mathvariant="normal">X</mi> </mrow> <mrow> <mo>-</mo> </mrow> </msup> </mrow> <mrow> <mi mathvariant="normal">m</mi> </mrow> </msubsup> </mrow> </semantics></math> (<b>d</b>) in the membrane were determined experimentally using Equation (7).</p> Full article ">Figure 6