User:Randomsalt/sandbox/Macro respirator

A respirator is a device designed to protect the wearer from inhaling hazardous atmospheres including lead fumes, vapors, gases and particulate matter such as dusts and airborne pathogens such as viruses. There are two main categories of respirators: the air-purifying respirator, in which respirable air is obtained by filtering a contaminated atmosphere, and the air-supplied respirator, in which an alternate supply of breathable air is delivered. Within each category, different techniques are employed to reduce or eliminate noxious airborne contaminants.

Air-purifying respirators range from relatively inexpensive, single-use, disposable face masks, known as filtering facepiece respirators, reusable models with replaceable cartridges called elastomeric respirators, to Powered air-purifying respirators (PAPR), which use a pump or fan to constantly move air through a filter and supply purified air into a mask, helmet or hood.History

[edit]

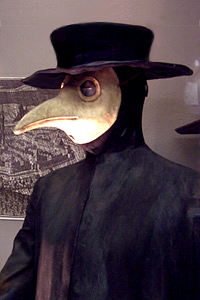

The history of protective respiratory equipment can be traced back as far as the first century, when Pliny the Elder (Template:Circa–79) described using animal bladder skins to protect workers in Roman mines from red lead oxide dust.[1] In the 16th century, Leonardo da Vinci suggested that a finely woven cloth dipped in water could protect sailors from a toxic weapon made of powder that he had designed.[2]

Alexander von Humboldt introduced a primitive respirator in 1799 when he worked as a mining engineer in Prussia.[3]

Julius Jeffreys first used the word "respirator" as a mask in 1836.[4]

In 1848, the first US patent for an air-purifying respirator was granted to Lewis P. Haslett[5] for his 'Haslett's Lung Protector,' which filtered dust from the air using one-way clapper valves and a filter made of moistened wool or a similar porous substance.[6] Hutson Hurd patented a cup-shaped mask in 1879 which became widespread in industrial use.[7]

Inventors in Europe included John Stenhouse, a Scottish chemist, who investigated the power of charcoal in its various forms, to capture and hold large volumes of gas. He built one of the first respirators able to remove toxic gases from the air, paving the way for activated charcoal to become the most widely used filter for respirators.[8] Irish physicist John Tyndall took Stenhouse's mask, added a filter of cotton wool saturated with lime, glycerin, and charcoal, and in 1871 invented a 'fireman's respirator', a hood that filtered smoke and gas from air, which he exhibited at a meeting of the Royal Society in London in 1874.[9] Also in 1874, Samuel Barton patented a device that 'permitted respiration in places where the atmosphere is charged with noxious gases, or vapors, smoke, or other impurities.'[10][11]

In the late 19th century, Miles Philips began using a "mundebinde" ("mouth bandage") of sterilized cloth which he refined by adapting a chloroform mask with two layers of cotton mull.[12]In the winter of 1910, Wu was given instructions from the Foreign Office of the Imperial Qing court[13] in Peking, to travel to Harbin to investigate an unknown disease that killed 99.9% of its victims.[14] This was the beginning of the large pneumonic plague epidemic of Manchuria and Mongolia, which ultimately claimed 60,000 lives.[15]

Wu was able to conduct a postmortem (usually not accepted in China at the time) on a Japanese woman who had died of the plague.[16][17] Having ascertained via the autopsy that the plague was spreading by air, Wu developed surgical masks into more substantial masks with layers of gauze and cotton to filter the air.[18][19] Gérald Mesny, a prominent French doctor who had come to replace Wu, refused to wear a mask and died days later of the plague.[17][18][16] The mask was widely produced, with Wu overseeing the production and distribution of 60,000 masks in a later epidemic, and it featured in many press images.[20][18]

Wu initiated a quarantine, arranged for buildings to be disinfected, and the old plague hospital to be burned down and replaced.[16] The measure that Wu is best remembered for was in asking for imperial sanction to cremate plague victims.[16] It was impossible to bury the dead because the ground was frozen, and the bodies could only be disposed of by soaking them in paraffin and burning them on pyres.[21] Cremation of these infected victims turned out to be the turning point of the epidemic; days after cremations began, plague began to decline and within months it had been eradicated.[22]

Wu chaired the International Plague Conference in Mukden (Shenyang) in April 1911, a historic event attended by scientists from the United States of America, the United Kingdom of Great Britain and Ireland, France, Germany, Italy, Austria-Hungary, the Netherlands, Russia, Mexico, and China.[23][24] The conference took place over three weeks and featured demonstrations and experiments.

Wu later presented a plague research paper at the International Congress of Medicine, London in August 1911 which was published in The Lancet in the same month.

At the plague conference, epidemiologists Danylo Zabolotny and Anna Tchourilina announced that they had traced the initial cause of the outbreak to Tarbagan marmot hunters who had contracted the disease from the animals. A tarabagan became the conference mascot.[23] However, Wu raised the question of why traditional marmot hunters had not experienced deadly epidemics before. He later published a work arguing that the traditional Mongol and Buryat hunters had established practices that kept their communities safe and he blamed more recent Shandong immigrants to the area (Chuang Guandong) for using hunting methods that captured more sick animals and increased risk of exposure.[25]

The First World War brought about the first need for mass-produced gas masks on both sides because of extensive use of chemical weapons. The German army successfully used poison gas for the first time against Allied troops at the Second Battle of Ypres, Belgium on April 22, 1915.[26] An immediate response was cotton wool wrapped in muslin, issued to the troops by May 1. This was followed by the Black Veil Respirator, invented by John Scott Haldane, which was a cotton pad soaked in an absorbent solution which was secured over the mouth using black cotton veiling.Lua error in package.lua at line 80: module 'Module:Footnotes/anchor id list/data' not found.

Seeking to improve on the Black Veil respirator, Cluny MacPherson created a mask made of chemical-absorbing fabric which fitted over the entire head.[27] A 50.5 cm × 48 cm (19.9 in × 18.9 in) canvas hood treated with chlorine-absorbing chemicals, and fitted with a transparent mica eyepiece.[28] Macpherson presented his idea to the British War Office Anti-Gas Department on May 10, 1915; prototypes were developed soon after.Lua error in package.lua at line 80: module 'Module:Footnotes/anchor id list/data' not found. The design was adopted by the British Army and introduced as the British Smoke Hood in June 1915; Macpherson was appointed to the War Office Committee for Protection against Poisonous Gases.[29] More elaborate sorbent compounds were added later to further iterations of his helmet (PH helmet), to defeat other respiratory poison gases used such as phosgene, diphosgene and chloropicrin. In summer and autumn 1915, Edward Harrison, Bertram Lambert and John Sadd developed the Large Box Respirator.[30]Template:Better source needed This canister gas mask had a tin can containing the absorbent materials by a hose and began to be issued in February 1916. A compact version, the Small Box Respirator, was made a universal issue from August 1916.[citation needed]

In the first gas masks of World War I, it was initially found that wood charcoal was a good absorbent of poison gases. Around 1918, it was found that charcoals made from the shells and seeds of various fruits and nuts such as coconuts, chestnuts, horse-chestnuts, and peach stones performed much better than wood charcoal. These waste materials were collected from the public in recycling programs to assist the war effort.[31]

The first effective filtering activated charcoal gas mask in the world was invented in 1915 by Russian chemist Nikolay Zelinsky.[32]

Also in World War I, since dogs were frequently used on the front lines, a special type of gas mask was developed that dogs were trained to wear.[33] Other gas masks were developed during World War I and the time following for horses in the various mounted units that operated near the front lines.[34] In America, thousands of gas masks were produced for American as well as Allied troops. Mine Safety Appliances was a chief producer. This mask was later used widely in industry.[35]

Prior to the 1970s, respirator standards were under the purview of the US Bureau of Mines (USBM). An example of an early respirator standard, Type A, established in 1926, was intended to protect against mechanically generated dusts produced in mines. These standards were intended to obviate miner deaths, noted to have reached 3,243 by 1907. However, prior to the Hawks Nest Tunnel Disaster, these standards were merely advisory, as the USBM had no enforcement power at the time.[36] After the disaster, an explicit approval program was established in 1934, along with the introduction of combination Type A/B/C respirator ratings, corresponding to Dusts/Fumes/Mists respectively, with Type D blocking all three.[37]

The Federal Coal Mine Health and Safety Act establishing MESA (later MSHA),[38] the Occupational Safety and Health Act of 1970, establishing NIOSH,[39] as well as other regulations established around the time, reshuffled regulatory authority for respirators, but nonetheless continued the use of USBM-era regulations.[37]Historically, respirators in the US had generally been approved by MESA/MSHA/NIOSH under federal regulation 30 CFR 11. On July 10, 1995, in response to respirators exhibiting "low initial efficiency levels", new 42 CFR 84 standards, including the N95 standard, were enforced under a three-year transition period,[40] ending on July 1, 1998. The standard for N95 respirators includes, but is not limited to, a filtration of at least 95% under a 0.3 micrometer[41] 200 milligram test load of sodium chloride. Standards and specifications are also subject to change.[42][43]

Once 42 CFR 84 was in effect, MSHA, under a proposed rule change to 30 CFR 11, 70, and 71, would withdraw from the approval process of rated respirators (outside of respirators used for mining).[44][45]Use

[edit]User seal check

[edit]

Fit testing

[edit]A respirator fit test checks whether a respirator properly fits the face of someone who wears it. The fitting characteristic of a respirator is the ability of the mask to separate a worker's respiratory system from ambient air.

This is achieved by tightly pressing the mask flush against the face (without gaps) to ensure an efficient seal on the mask perimeter. Because wearers cannot be protected if there are gaps, it is necessary to test the fit before entering into contaminated air. Multiple forms of the test exist.

Scientific studies have shown that if the mask size and shape is correctly fitted to the employees’ face, they will be better protected in hazardous workplaces.[47]

Facial hair such as a beard can interfere with proper fit.[48]Selection

[edit]Air-purifying respirators are respirators that draw in the surrounding air and purify it before it is breathed (unlike air-supplying respirators, which are sealed systems, with no air intake, like those used underwater). Air-purifying respirators filter particulates, gases, and vapors from the air, and may be negative-pressure respirators driven by the wearer's inhalation and exhalation, or positive-pressure units such as powered air-purifying respirators (PAPRs).

According to the NIOSH Respirator Selection Logic, air-purifying respirators are recommended for concentrations of hazardous particulates or gases that are greater than the relevant occupational exposure limit but less than the immediately dangerous to life or health level and the manufacturer's maximum use concentration, subject to the respirator having a sufficient assigned protection factor. For substances hazardous to the eyes, a respirator equipped with a full facepiece, helmet, or hood is recommended. Air-purifying respirators are not effective during firefighting, in oxygen-deficient atmosphere, or in an unknown atmosphere; in these situations a self-contained breathing apparatus is recommended instead.[49]Filtration

[edit]

Mechanical filter respirators retain particulate matter such as dust created during woodworking or metal processing, when contaminated air is passed through the filter material. Wool is still used today as a filter, along with plastic, glass, cellulose, and combinations of two or more of these materials. Since the filters cannot be cleaned and reused and have a limited lifespan, cost and disposability are key factors. Single-use, disposable and replaceable-cartridge models exist.[51]

Mechanical filters remove contaminants from air in the following ways:[52][53]

- by interception when particles following a line of flow in the airstream come within one radius of a fiber and adhere to it;[51]

- by impaction, when larger particles unable to follow the curving contours of the airstream are forced to embed in one of the fibers directly; this increases with diminishing fiber separation and higher air flow velocity[51]

- by an enhancing mechanism called diffusion, where gas molecules collide with the smallest particles, especially those below 100 nm in diameter, which are thereby impeded and delayed in their path through the filter; this effect is similar to Brownian motion and increases the probability that particles will be stopped by either of the two mechanisms above; it becomes dominant at lower air flow velocities[51]

- by using electret filter material (usually, electrospun plastic fibers) to attract or repel particles with an electrostatic charge, so that they are more likely to collide with the filter surface[52][53]

More obscure mechanisms include:

- by using certain coatings on the fibers that kill or deactivate infectious particles colliding with them (such as salt)[54]

- by using gravity and allowing particles to settle into the filter material (this effect is typically negligible)[55]

Canisters and chemical cartridges

[edit]

A respirator cartridge or gas mask canister is a type of filter that removes gases, volatile organic compounds (VOCs), and other vapors from air through adsorption, absorption, or chemisorption. It is one of two basic types of filters used by air-purifying respirators. The other is a mechanical filter, which removes only particulates. Hybrid filters combine the two.

Workplace air that is polluted with fine particulate matter or noxious gases but that contains enough oxygen (in the US, this is ruled to be a concentration above 19.5%; in the Russian Federation, above 18%[citation needed]), can be rendered safe via air-purifying respirators. Cartridges are of different types, and must be chosen correctly and replaced on an appropriate schedule.[56][57]Regulation

[edit]United States 30 CFR 11

[edit]

Prior to the approval of 42 CFR 84, MSHA and NIOSH approved respirators under 30 CFR 11. Non-powered respirator filters were classified based on their design against a contaminant, including substances like 'dusts', 'fumes', 'mists', radionuclides, and asbestos. 'Dust/Mist' was usually tested with silica, and 'fume' was usually tested with lead fume. The most popular respirator filters were often referred to as 'DM' (Dust/Mist) or 'DFM' (Dust/Fume/Mist) in CDC and NIOSH literature as shorthand.[58] Non-powered filters were also classified under the HEPA specification, if applicable.[59]

Only 30 CFR 11 HEPA filters were permitted by NIOSH for the prevention of tuberculosis.[60]

NIOSH was concerned about users choosing inappropriate respirators, like confusion over choosing 'dust/mist' or 'dust/fume/mist' respirators with regards to particle penetration, so proposed Part 84 rules in 1994 dropped the contaminant/HEPA classification for most respirators in favor of three specifications, Type A, B and C, each representing filtration of 99.97%, 99%, and 95% respectively, with Type A proposed to be used in place of HEPA for non-powered respirators.[61][59]

| Particulate | Respirator

Approval |

Maximum

Dust Penetration |

Minimum

Efficiency Level |

Permitted for |

|---|---|---|---|---|

| 158.4 mg silica | Single-use Dust/Mist filters | 1.8 mg | 98.86% | No |

| 158.4 mg, usually silica | Replaceable Dust/Mist filters | 1.5 mg | 99.05% | No |

| 0.3 micron DOP | HEPA (includes

Dust/Mist approval)[62] |

N/A | 99.97% | Yes |

United States 42 CFR 84

[edit]

Under the current revision of Part 84 established in 1995, NIOSH established nine classifications of approved particulate filtering respirators based on a combination of the respirator series and efficiency level. The first part of the filter's classification indicates the series using the letters N, R, or P to indicate the filter's resistance to filtration efficiency degradation when exposed to oil-based or oil-like aerosols (e.g., lubricants, cutting fluids, glycerine, etc.).[63][64][65] Definitions and intended use for each series is indicated below.[66]

- N for not resistant to oil. Used when oil particulates are not present. Tested using sodium chloride particles.

- R for resistant to oil. Used when oil particulates are present and the filter is disposed of after one shift. Tested using dioctyl phthalate (DOP) oil particles.

- P for oil-proof. Used when oil particulates are present and the filter is re-used for more than one shift. Tested with DOP oil particles.

The second value indicates the minimum efficiency level of the filter. When tested according to the protocol established by NIOSH each filter classification must demonstrate the minimum efficiency level indicated below.

| Particulate | Respirator

Class |

Minimum

Efficiency Level |

Permitted for TB |

|---|---|---|---|

| NaCl (N) or DOP (R,P) | N95, R95, P95 | 95% | Yes |

| N99, R99, P99 | 99% | ||

| N100, R100, P100, HE | 99.97% |

All respirator types are permitted for TB.[67][61] Class-100 filters can block asbestos.[68] For N type filters, a 200 mg load of NaCl is used, with and undefined service time. For R type filters, a 200 mg of DOP is used, with a defined service time of "one work shift". For P type filters, an indefinite amount of DOP is used until filtration efficiency stabilizes.[69] P100 filters, under 42 CFR part 84, are the only filters permitted to be magenta in color.[70] HE (high-efficiency) labeled filters are only provided for powered air-purifying respirators. HE-marked filters are 99.97% efficient against 0.3 micron particles and are oil-proof.[71][72][73]

Since filters are tested against the by definition most penetrating particle size of 0.3 μm, an APR with a P100 classification would be at least 99.97% efficient at removing particles of this size.[65] Particles with a size both less than and greater than 0.3 μm may be filtered at an efficiency greater than 99.97%.[74][75] However, this may not always be the case, as the most penetrating particle size for N95s was measured to be below 0.1 μm, as opposed to the predicted size of between 0.1 and 0.3 μm.[76]United States ANSI canister and chemical cartridge

[edit]Lua error in Module:Excerpt at line 29: invalid option '% ' to 'format'.

United States firefighter breathing apparatus

[edit]In addition to the above regulations, firefigher self-contained breathing apparatus have the following regulations applied:

In the United States and Canada, SCBAs used in firefighting must meet guidelines established by the National Fire Protection Association, NFPA Standard 1981. If an SCBA is labeled as "1981 NFPA compliant", it is designed for firefighting. The current version of the standard was published in 2018.[77] These standards are revised every five years. Similarly, the National Institute for Occupational Safety and Health (NIOSH) has a certification program for SCBA that are intended to be used in chemical, biological, radiological, and nuclear (CBRN) environments.

Any SCBA supplied for use in Europe must comply with the requirements of the Personal Protective Equipment Directive (89/686/EEC). In practice this usually means that the SCBA must comply with the requirements of the European Standard EN 137:2006. This includes detailed requirements for the performance of the SCBA, the marking required, and the information to be provided to the user. Two classes of SCBA are recognised, Type 1 for industrial use and Type 2 for firefighting. Any SCBA conforming to this standard will have been verified to reliably operate and protect the user from -30 °C to +60 °C under a wide range of severe simulated operational conditions.European respirator regulations

[edit]The EN 149 standard defines performance requirements for three classes of particle-filtering half masks: FFP1, FFP2 and FFP3. The protection provided by an FFP2 (or FFP3) mask includes the protection provided by a mask of the lower-numbered classes.

A mask conforming to the standard must have its class written on it, along with the name of the standard and its year of publication, as well as any applicable option codes, e.g. “EN 149:2001 FFP1 NR D”. Some manufacturers use in addition the colour of the elastic band to identify the mask class, however, the EN 149 standard does not specify any such colour coding and different manufacturers have used different colour schemes.

| Class[78] | Filter penetration limit (at 95 L/min air flow) | Inward leakage | Typical elastic band |

|---|---|---|---|

| FFP1 | Filters at least 80% of airborne particles | <22% | Yellow |

| FFP2 | Filters at least 94% of airborne particles | <8% | Blue or White |

| FFP3 | Filters at least 99% of airborne particles | <2% | Red |

European standard EN 143 defines the 'P' classes of particle filters that can be attached to a face mask. These filters are typically used on reusable respirators, like elastomeric respirators.[79]

| Standard | Class | Filter type | Filter penetration limit (at 95 L/min air flow) | Inward leakage | Typical elastic band |

|---|---|---|---|---|---|

| EN 14683[80] | Type I | Mask | Less than 98% droplet filtration, intended for use by patients | N/A | N/A |

| Type II | Not fluid-resistant, 98% droplet filtration, intended for use by healthcare workers in droplet-free environments | ||||

| Type IIR | Fluid-resistant, 98% droplet filtration, surgical | ||||

| EN 143 | P1 | Attachment | Filters at least 80% of airborne particles | N/A | N/A |

| P2 | Filters at least 94% of airborne particles | ||||

| P3 | Filters at least 99.95% of airborne particles |

European chemical cartridge regulations

[edit]Facepieces

[edit]Respirator types

[edit]The NIOSH N95

[edit]NIOSH N95 use during pandemics

[edit]Misuse

[edit]References

[edit]- ^ Template:Cite wikisource

- ^ Women in the US Military – History of Gas Masks. Chnm.gmu.edu (11 September 2001).

- ^ Ueber die unterirdischen Gasarten und die Mittel ihren Nachtheil zu vermindern (en) (1799).

- ^ David Zuck (1990). "Julius Jeffreys: Pioneer of humidification" (PDF). Proceedings of the History of Anaesthesia Society. 8b: 70–80. Archived (PDF) from the original on 4 November 2021. Retrieved 16 August 2020.

- ^ Christianson, Scott (2010). Fatal Airs: The Deadly History and Apocalyptic Future of Lethal Gases that Threaten Our World. ABC-CLIO. ISBN 9780313385520.

- ^ Template:Cite patent Archived 8 March 2021 at the Wayback Machine

- ^ Template:Cite patent

- ^ Britain, Royal Institution of Great (1858). Notices of the Proceedings at the Meetings of the Members of the Royal Institution, with Abstracts of the Discourses. W. Nicol, Printer to the Royal Institution. p. 53.

- ^ Tyndall, John (1873). "On Some Recent Experiments with a Fireman's Respirator". Proceedings of the Royal Society of London. 22: 359–361. Bibcode:1873RSPS...22R.359T. ISSN 0370-1662. JSTOR 112853.

- ^ Gas Mask Development (1926).

- ^ Template:Cite patent Archived 8 March 2021 at the Wayback Machine

- ^ Lowry, H. C. (1947). "Some Landmarks in Surgical Technique". The Ulster Medical Journal. 16 (2): 102–113. PMC 2479244. PMID 18898288.

- ^ The Chinese Doctor Who Beat the Plague (en-US) (2018-12-20).

- ^ "Obituary: WU LIEN-TEH, M.D., Sc.D., Litt.D., LL.D., M.P.H". Br Med J. 1 (5170): 429–430. 6 February 1960. doi:10.1136/bmj.1.5170.429-f. ISSN 0007-1447. PMC 1966655.

- ^ Flohr, Carsten (1996). "The Plague Fighter: Wu Lien-teh and the beginning of the Chinese public health system". Annals of Science. 53 (4): 361–380. doi:10.1080/00033799608560822. ISSN 0003-3790. PMID 11613294.

- ^ a b c d Lee, Kam Hing; Wong, Danny Tze-ken; Ho, Tak Ming; Ng, Kwan Hoong (2014). "Dr Wu Lien-teh: Modernising post-1911 China's public health service". Singapore Medical Journal. 55 (2): 99–102. doi:10.11622/smedj.2014025. PMC 4291938. PMID 24570319.

- ^ a b Ma, Zhongliang; Li, Yanli (2016). "Dr. Wu Lien Teh, plague fighter and father of the Chinese public health system". Protein & Cell. 7 (3): 157–158. doi:10.1007/s13238-015-0238-1. ISSN 1674-800X. PMC 4791421. PMID 26825808.

- ^ a b c Wilson, Mark (24 March 2020). The untold origin story of the N95 mask (en-US).

- ^ Wu Lien-te; World Health Organization (1926). A Treatise on Pneumonic Plague. Berger-Levrault.

- ^ Lynteris, Christos (18 August 2018). "Plague Masks: The Visual Emergence of Anti-Epidemic Personal Protection Equipment". Medical Anthropology. 37 (6): 442–457. doi:10.1080/01459740.2017.1423072. hdl:10023/16472. ISSN 0145-9740. PMID 30427733.

- ^ "Obituary: Wu Lien-Teh". The Lancet. Originally published as Volume 1, Issue 7119. 275 (7119): 341. 6 February 1960. doi:10.1016/S0140-6736(60)90277-4. ISSN 0140-6736.

- ^ Mates, Lewis H. (29 April 2016). Encyclopedia of Cremation. Routledge. pp. 300–301. ISBN 978-1-317-14383-3.

- ^ a b Summers, William C. (11 December 2012). The Great Manchurian Plague of 1910-1911: The Geopolitics of an Epidemic Disease. Yale University Press. ISBN 978-0-300-18476-1.

- ^ Inaugural address delivered at the opening of the International Plague Conference, Mukden, April 4th, 1911 (en) (1911).

- ^ Lynteris, Christos (1 September 2013). "Skilled Natives, Inept Coolies: Marmot Hunting and the Great Manchurian Pneumonic Plague (1910–1911)". History and Anthropology. 24 (3): 303–321. doi:10.1080/02757206.2012.697063. ISSN 0275-7206. S2CID 145299676.

- ^ First Usage of Poison Gas (en).

- ^ Victor Lefebure (1923). The Riddle of the Rhine: Chemical Strategy in Peace and War. The Chemical Foundation Inc. ISBN 0-585-23269-5.

- ^ Macpherson Gas Hood . Accession #980.222. The Rooms Provincial Museum Archives (St. John's, NL).

- ^ Biographical entry Macpherson, Cluny (1879 - 1966).

- ^ The UK. The Gas Mask Database.

- ^ Once Worthless Things that have Suddenly Become of Value, Popular Science monthly, December 1918, page 80, scanned by Google Books

- ^ Kozhevnikov, A B (2004). Stalin's great science: the times and adventures of Soviet physicists (illustrated, reprint ed.). Imperial College Press. pp. 10–11. ISBN 978-1-86094-419-2. Retrieved April 28, 2009.

- ^ "Gas-Masks for Dogs / Dumb Heroes of the Fighting Front", Popular Science monthly, December 1918, page 75, Scanned by Google Books

- ^ "Gas Masks to Guard Horses and Dogs in War" Popular Mechanics, July 1934, bottom pg. 75

- ^ Pittsburgh Post-Gazette, November 30, 1960

- ^ Howard W., Spencer. The Historic and Cultural Importance of the HAWKS NEST TUNNEL DISASTER. American Society of Safety Professionals.

- ^ a b Spelce, David; Rehak, Timothy R; Meltzer, Richard W; Johnson, James S (2019). "History of U.S. Respirator Approval (Continued) Particulate Respirators". J Int Soc Respir Prot. 36 (2): 37–55. PMC 7307331. PMID 32572305.

- ^ Federal Coal Mine and Safety Act of 1969. US Department of Labor, US Mine Safety and Health Administration.

- ^ US EPA, OP (2013-02-22). Summary of the Occupational Safety and Health Act (en).

- ^ DEPARTMENT OF HEALTH AND HUMAN SERVICES Public Health Service 42 CFR Part 84 RIN 0905–AB58 Respiratory Protective Devices. US Federal Register (8 June 1995).

- ^ 42 CFR 84 Respiratory Protective Devices. NIOSH (1995-08-25).

- ^ Herring Jr., Ronald N. (1997). "42 CFR Part 84: It's time to change respirators... but how?". Engineer's Digest. pp. 14–23.

- ^ NIOSH Guide to the Selection and Use of Particulate Respirators Certified Under 42 CFR 84. 1996.

- ^ DEPARTMENT OF HEALTH AND HUMAN SERVICES Public Health Service 42 CFR Part 84. US Federal Register.

- ^ CHANGES IN OCCUPATIONAL SAFETY REGS WILL PERMIT BETTER RESPIRATORS TO PROTECT AGAINST DUST AND DISEASE. NIOSH (1995-06-02).

- ^ Filtering out Confusion: Frequently Asked Questions about Respiratory Protection, User Seal Check (2018).

- ^ Cite error: The named reference

User:Randomsalt/sandbox/Respirator fit test Zhuang-2003was invoked but never defined (see the help page). - ^ To Beard or not to Beard? That's a good Question! | | Blogs | CDC (en-us) (2 November 2017).

- ^ Bollinger, Nancy (2004-10-01). "NIOSH respirator selection logic". U.S. National Institute for Occupational Safety and Health: 5–16. doi:10.26616/NIOSHPUB2005100. Archived from the original on 15 July 2020. Retrieved 2020-04-20.

- ^ What is PM0.3 and Why Is It Important? (6 May 2019).

- ^ a b c d e Mechanisms of Filtration for High Efficiency Fibrous Filters - Application Note ITI-041.

- ^ a b perry, J.L.; Agui, J.H.; Vijayakumar, R. (May 2016), Submicron and Nanoparticulate Matter Removal by HEPA-Rated Media Filters and Packed Beds of Granular Materials (PDF), NASA

- ^ a b Guidance for Filtration and Air-Cleaning Systems to Protect Building Environments from Airborne Chemical, Biological, or Radiological Attacks. CDC NIOSH (April 2003). DOI:10.26616/NIOSHPUB2003136.

- ^ Quan, Fu-Shi; Rubino, Ilaria; Lee, Su-Hwa; Koch, Brendan; Choi, Hyo-Jick (2017-01-04). "Universal and reusable virus deactivation system for respiratory protection". Scientific Reports. 7 (1): 39956. Bibcode:2017NatSR...739956Q. doi:10.1038/srep39956. ISSN 2045-2322. PMC 5209731. PMID 28051158.

- ^ Standard for Dust Mask.

- ^ Occupational Safety and Health Administration (2019). Respirator Change Schedules (Respiratory Protection eTool) (en).

- ^ David S. DeCamp, Joseph Costantino, Jon E. Black (November 2004). Estimating Organic Vapor Cartridge Service Life (PDF). Kennedy Circle Brooks City-Base: Air Force Institute for Operational Health Risk Analysis Directorate. p. 53. Archived (PDF) from the original on October 5, 2019. Retrieved 9 November 2019.

{{cite book}}: CS1 maint: multiple names: authors list (link) - ^ NIOSH Recommended Guidelines for Personal Respiratory Protection of Workers in Health-care Facilities Potentially Exposed to Tuberculosis. 1992.

- ^ a b c Spelce, David; Rehak, Timothy R; Meltzer, Richard W; Johnson, James S (2019). "History of U.S. Respirator Approval (Continued) Particulate Respirators". J Int Soc Respir Prot. 36 (2): 37–55. PMC 7307331. PMID 32572305.

- ^ DEPARTMENT OF HEALTH AND HUMAN SERVICES Centers for Disease Control and Prevention Guidelines for Preventing the Transmission of Mycobacterium Tuberculosis in Health-Care Facilities, 1994. US Federal Register.

- ^ a b DEPARTMENT OF HEALTH AND HUMAN SERVICES Public Health Service 42 CFR Part 84. US Federal Register.

- ^ Differences and Limitations Between Part 11 Particulate Respirators and Part 84 Particulate Respirators. NIOSH (1996-06-20).

- ^ a b 42 CFR Part 84 - Approval of Respiratory Protective Devices. United States Government Publishing Office (February 6, 2020).

- ^ Respirator Trusted-Source Information Section 1: NIOSH-Approved Respirators. Centers for Disease Control and Prevention (January 29, 2018).

- ^ a b NIOSH Guide to the Selection and Use of Particulate Respirators. Centers for Disease Control and Prevention (June 6, 2014).

- ^ OSHA Technical Manual Section 8VII: Chapter 2 Respiratory Protection Appendix 2-4.

- ^ TB Respiratory Protection Program In Health Care Facilities Administrator's Guide. U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health (September 1999). DOI:10.26616/NIOSHPUB99143.

- ^ NIOSH Pocket Guide - Asbestos. CDC.

- ^ DHHS Pub 96-101 NIOSH Guide to the Selection & Use of Particulate Respirators Certified Under 42 CFR 84. NIOSH.

- ^ Herring Jr., Ronald N. (1997). "42 CFR Part 84: It's time to change respirators... but how?". Engineer's Digest. pp. 14–23.

- ^ Considerations for Optimizing the Supply of Powered Air-Purifying Respirators (PAPRs) (en-us) (2020-04-19).

- ^ Vanessa, Roberts (Fall 2014). "To PAPR or Not to PAPR?". Canadian Journal of Respiratory Therapy. 50 (3): 87–90. PMC 4456839. PMID 26078617.

- ^ Understanding Respiratory Protection Against SARS (en-us) (2020-04-09).

- ^ NIOSH Guide to the Selection and Use of Particulate Respirators Appendix E: Commonly Asked Questions and Answers About Part 84 Respirators. Centers for Disease Control and Prevention (June 6, 2014).

- ^ CDC - NIOSH Publications and Products - Appendices for 96-101 (en-us) (2018-10-16).

- ^ Lee, Byung Uk; Yermakov, Mikhail; Grinshpun, Sergey A. (2005). "Filtering Efficiency of N95- and R95-Type Facepiece Respirators, Dust-Mist Facepiece Respirators, and Surgical Masks Operating in Unipolarly Ionized Indoor Air Environments" (PDF). Aerosol and Air Quality Research. 5 (1): 25–38. doi:10.4209/aaqr.2005.06.0003. Archived (PDF) from the original on 20 January 2022. Retrieved 4 July 2024.

- ^ NFPA.

- ^ Fiche pratique de sécurité ED 105. Appareils de protection respiratoire et métiers de la santé. INRS.

- ^ Fiche pratique de sécurité ED 105. Appareils de protection respiratoire et métiers de la santé. inrs.fr. INRS.

- ^ COVID-19 Technical Specifications for Personal Protective Equipment and Related IPC supplies. World Health Organization.

- ^ NF EN 149+A1. www.boutique.afnor.org (September 2009). alternative source

- ^ LEGISLATION AND STANDARDS - 3M.